What Is a Forklift Battery Pack?

A forklift battery pack is a collection of battery cells designed to provide power to electric forklifts. It stores energy for operation and can come in different types, including lead-acid and lithium-ion.

How Does a Forklift Battery Pack Work?

A forklift battery pack works by converting stored chemical energy into electrical energy. When the forklift is in use, the battery releases this energy to power the motor, allowing the forklift to lift and move loads.

What Are the Different Types of Forklift Battery Packs?

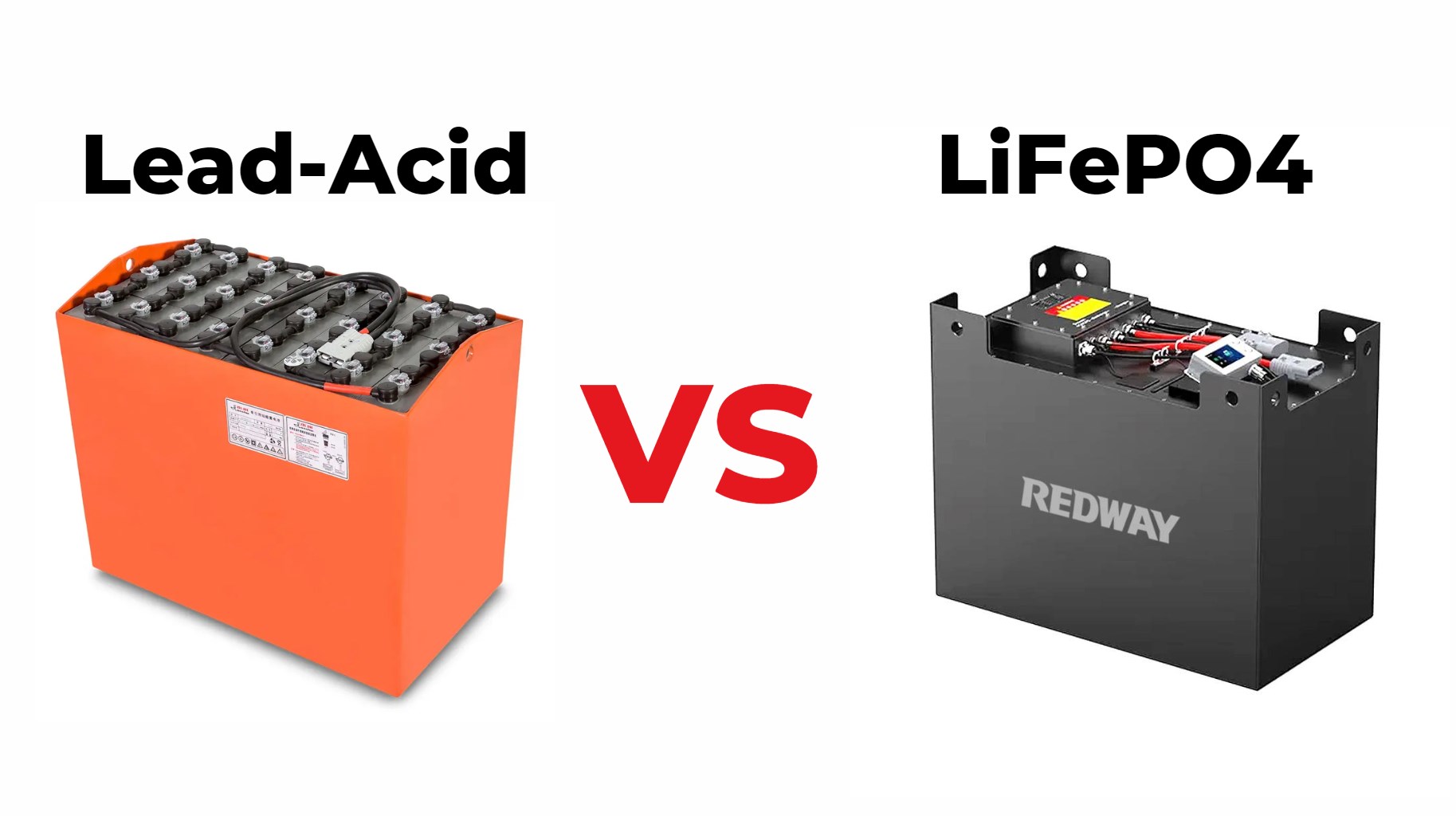

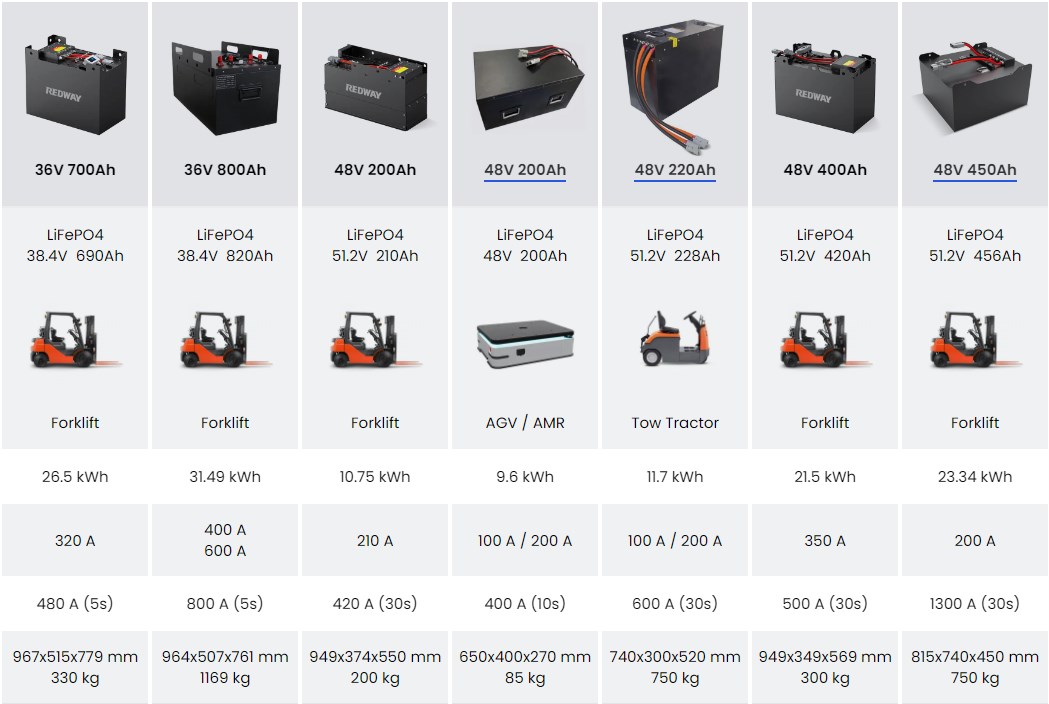

The main types of forklift battery packs include lead-acid batteries, which are common and cost-effective, and lithium-ion batteries, which offer faster charging and longer lifespans. Other types include AGM (Absorbed Glass Mat) batteries that require less maintenance.

- Lead-Acid Batteries: Traditional option known for affordability but requires regular maintenance.

- Lithium-Ion Batteries: Increasingly popular due to their longer lifespan, faster charging times, and lower maintenance needs.

What Are the Advantages of Using Forklift Battery Packs?

Advantages of using forklift battery packs include lower operating costs, reduced maintenance needs (especially with lithium-ion), longer lifespan, and faster charging times. They also help improve efficiency in warehouse operations.

- Enhanced efficiency with lower energy consumption.

- Longer operational life compared to traditional batteries.

- Reduced maintenance requirements, especially with lithium-ion technology.

How to Choose the Right Forklift Battery Pack?

To choose the right forklift battery pack, consider factors like compatibility with your forklift model, capacity requirements, charging time, maintenance needs, and overall cost. Assessing these factors ensures optimal performance for your operations.

Consider factors such as:

- Compatibility with your forklift model.

- Voltage requirements based on operational needs.

- Amp-hour ratings that match usage patterns.

What Maintenance Is Required for Forklift Battery Packs?

Maintenance for forklift battery packs includes regularly checking fluid levels (for lead-acid), cleaning terminals, ensuring proper charging practices, and scheduling periodic inspections to prolong battery life.

Know More:

What Are Lithium Forklift Batteries?

What Are Used Forklift Batteries?

What Are Reconditioned Forklift Batteries?

How Can You Effectively Recondition a Forklift Battery?

What Is a Forklift Battery Pack?

How Do Forklift Battery Packs Compare to Traditional Batteries?

Forklift battery packs generally offer better performance than traditional batteries. Lithium-ion packs charge faster, last longer (up to 3,000 cycles), and require less maintenance compared to lead-acid batteries, which typically last around 1,500 cycles.

What Are Common Applications for Forklift Battery Packs?

Common applications for forklift battery packs include warehouses, manufacturing facilities, distribution centers, and retail environments. They power electric forklifts used for lifting and transporting goods efficiently.

- Warehousing

- Manufacturing

- Distribution centers

They provide reliable power for various material handling tasks.

What Is the Lifespan of a Forklift Battery Pack?

The lifespan of a forklift battery pack varies: lead-acid batteries typically last around 5 years or 1,500 cycles, while lithium-ion batteries can last over 10 years or 3,000 cycles with proper maintenance.

How Do Environmental Conditions Affect Battery Performance?

Environmental conditions can significantly affect battery performance. Extreme temperatures can reduce efficiency; ideal operating conditions are typically between 32°F and 113°F (0°C to 45°C) for optimal performance.

What Safety Measures Should Be Taken When Handling Forklift Batteries?

When handling forklift batteries, wear protective gear like gloves and goggles. Ensure proper ventilation during charging to avoid gas buildup and follow manufacturer guidelines for safe handling and maintenance practices.

Expert Views

“Understanding forklift battery packs is essential for optimizing operations,” states an expert from Redway. “Choosing the right type can significantly improve efficiency and reduce long-term costs.”

Conclusion

In summary, forklift battery packs are vital components that power electric forklifts across various industries. By understanding their types, advantages, maintenance needs, and applications, users can make informed decisions that enhance productivity and sustainability in their operations.

FAQ Section

- What is the average lifespan of a forklift battery pack?

Lead-acid packs typically last around 3 to 5 years while lithium-ion packs can last up to 10 years or more. - How often should I maintain my forklift battery pack?

Lead-acid batteries require regular checks and watering; lithium-ion batteries need minimal maintenance but should be monitored periodically. - Can I use any charger for my forklift battery pack?

No, always use chargers specifically designed for your type of battery pack to ensure safety and optimal performance.