Optimizing Clark forklift battery charging involves using proper charging techniques, maintaining battery health, and employing smart chargers to extend battery life and performance. Implementing best practices ensures efficient energy use, reduces downtime, and prolongs forklift operational reliability.

What Are the Key Factors Affecting Clark Forklift Battery Charging?

Several critical factors influence the efficiency of Clark forklift battery charging, including battery type, charger compatibility, ambient temperature, and charging cycles. Proper attention to these elements helps maximize battery lifespan.

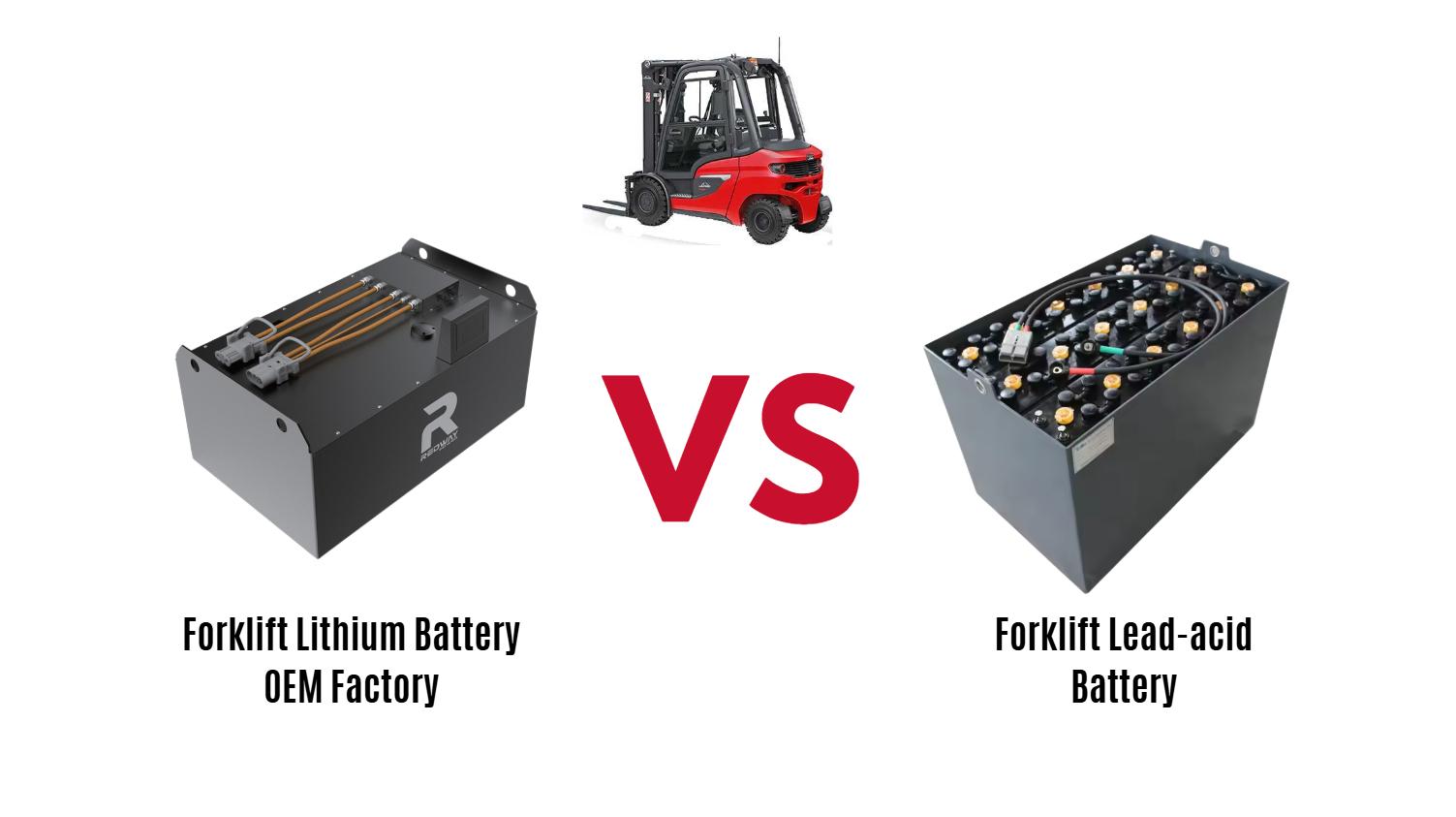

Clark forklifts typically use lithium iron phosphate (LiFePO4) or lead-acid batteries, with LiFePO4 becoming more common due to superior cycle life and safety. The charger must match battery specifications in voltage, current, and charging protocol to avoid under- or overcharging. Ambient temperature affects chemical reactions during charging; extreme heat or cold can degrade battery cells. Charging cycles and depth of discharge influence battery capacity — shallow cycles and full charges promote longevity. Businesses benefit from monitoring these factors to optimize overall charging efficiency.

How Should You Charge a Clark Forklift Battery to Maximize Its Lifespan?

The best practice involves charging the battery in a cool, dry environment using a smart charger that prevents overcharging and supports balanced cell charging. Avoid deep discharges and schedule regular maintenance.

Start by ensuring the battery is between 20% to 80% charge before connecting it to the charger. Using a charger with temperature compensation and automatic cut-off prevents damage. Avoid rapid charge cycles that cause excessive heat and wear. Regular equalization charges help balance cell voltage, especially in lead-acid batteries, reducing sulfation. For LiFePO4 batteries, maintaining consistent charging protocols avoids capacity loss. Redway Battery’s chargers integrate advanced algorithms for optimal charging control, enhancing effectiveness and extending battery life.

Which Charging Systems and Technologies Are Best for Clark Forklift Batteries?

Advanced smart chargers with microprocessor controls and regenerative braking recharge systems provide the best results for Clark forklift batteries, improving both safety and efficiency.

Smart chargers continuously monitor battery voltage, temperature, and current, adjusting the charging rate for efficiency and safety. Regenerative braking systems capture kinetic energy during forklift operation, subtly recharging the battery and reducing charge cycle frequency. Pulse charging technology can also reduce battery sulfation and heating. Redway Battery‘s engineered LiFePO4 packs are compatible with these technologies, delivering consistent performance in various operational settings.

| Charger Type |

Key Feature |

Benefits |

Compatibility |

| Smart Charger |

Microprocessor-controlled |

Prevents overcharge, extends lifespan |

LiFePO4 & lead-acid batteries |

| Regenerative Systems |

Energy recovery from braking |

Improves energy efficiency |

LiFePO4 suited forklifts |

| Pulse Chargers |

Pulsed current to reduce sulfation |

Maintains battery health |

Lead-acid primarily |

Why Is Battery Maintenance Crucial for Clark Forklift Charging Optimization?

Proper maintenance prevents capacity loss, ensures safety, and reduces unexpected downtime by keeping batteries clean, balanced, and adequately hydrated.

Maintenance includes cleaning terminals to avoid corrosion that disrupts current flow, checking electrolyte levels in lead-acid batteries, and inspecting for physical damage or swelling. Balancing cells ensures uniform charge distribution, a key factor in battery health. For LiFePO4 batteries, which require less frequent maintenance, regular firmware updates on smart chargers optimize performance. Redway Battery provides comprehensive maintenance guides and support to help businesses implement effective upkeep routines.

When Should You Charge Clark Forklift Batteries for Maximum Efficiency?

Charging should ideally occur during off-peak hours or scheduled breaks when forklifts are idle to avoid operational disruption and reduce energy costs.

Charging during cooler parts of the day minimizes thermal stress and energy wastage. Night or off-shift charging benefits from lower electricity rates and less demand on power grids. Batteries should never remain in a discharged state for prolonged periods, so scheduling charging sessions after moderate use is critical. Incorporating automated charging schedules using smart systems enhances consistency and efficiency. Redway Battery’s monitoring software supports predictive charging alerts, helping facilities optimize timing.

Can Charging Practices Impact Clark Forklift Battery Safety?

Yes, improper charging can lead to overheating, swelling, or even hazardous failures. Following manufacturer guidelines and smart charging protocols is essential for safe operation.

Batteries are sensitive to overvoltage and rapid charging, which can cause thermal runaway or permanent damage. Using chargers with built-in safety features such as temperature cutoffs, voltage regulation, and short circuit protection mitigates risks. Storing batteries correctly and avoiding exposure to moisture or extreme heat further maintains safety. With Redway Battery’s LiFePO4 technology, built-in safety features reduce the risk of fire or explosion common in older battery chemistries.

How Does Environmental Temperature Affect Clark Forklift Battery Charging?

Temperature influences the chemical reactions inside the battery, impacting charging efficiency and lifespan. Optimal charging occurs within manufacturer-defined temperature ranges.

Cold temperatures slow down electrolyte movement, increasing internal resistance and leading to incomplete charges. Excessive heat accelerates chemical degradation and water loss in lead-acid batteries. Smart chargers with temperature sensors adjust charging profiles to compensate for variations. Charging in a controlled environment enhances both battery safety and performance reliability. Redway Battery designs accommodate wide thermal ranges with robust battery management systems (BMS).

What Role Does Battery Management System (BMS) Play in Optimizing Charging?

The BMS monitors battery health, controls charging currents, balances cells, and prevents overcharge or deep discharge, significantly enhancing battery lifespan and performance.

A sophisticated BMS provides real-time data on temperature, voltage, and charge status, automatically adjusting the charging process to prevent damage. Battery balancing ensures all cells share voltage evenly, avoiding premature failure. It also alerts operators to maintenance needs or abnormal conditions. Redway Battery integrates advanced BMS solutions within their LiFePO4 packs, enabling intelligent, adaptive charging and safety controls.

Are There Cost Benefits to Optimizing Clark Forklift Battery Charging?

Absolutely. Optimized charging lowers energy consumption, decreases battery replacements, and reduces forklift downtime, saving significant operational costs over time.

Efficient charging reduces peak power demands and extends battery cycle life, lowering replacement frequency and maintenance expenses. Minimizing unexpected failures also means fewer interruptions in operations, boosting productivity. Investing in high-quality batteries and smart chargers from trusted manufacturers—like Redway Battery—yields strong ROI through improved reliability and energy efficiency.

Redway Expert Views

Optimizing forklift battery charging is no longer just about plugging in and waiting. With advancements in LiFePO4 technology and smart charging systems, companies can significantly enhance battery life, safety, and operational uptime. Redway Battery’s commitment to innovation and customized solutions empowers forklift operators worldwide to achieve next-level efficiency in energy management, ensuring smoother workflows and reduced environmental impact.” – Redway Battery Engineering Team

Conclusion

Optimizing Clark forklift battery charging requires understanding critical factors such as battery chemistry, charger compatibility, environmental conditions, and maintenance best practices. Employ smart charging technology and implement systematic scheduling to maximize battery life, safety, and operational efficiency. Partnering with a trusted supplier like Redway Battery ensures access to high-performance lithium battery solutions and expert support, creating long-term value for forklift operations.

FAQs

1. Can I use any charger to charge a Clark forklift battery?

No. Chargers must be compatible with the battery chemistry and specifications to avoid damage and ensure safe, efficient charging.

2. How often should Clark forklift batteries be charged?

Ideally, batteries should be charged after each shift or when they reach 20-30% discharge to preserve capacity and prevent deep discharge damage.

3. Does temperature affect how I should charge my forklift battery?

Yes. Charging in extreme temperatures can harm battery health; use chargers with temperature compensation and consider ambient temperature control.

4. How long does it take to fully charge a Clark forklift battery?

Charging times vary by battery size and charger type, but typical LiFePO4 batteries fully charge within 2 to 4 hours using smart chargers.

5. What maintenance is needed for Clark forklift batteries?

Maintenance includes cleaning terminals, inspecting cables, checking electrolyte levels for lead-acid, and ensuring balanced charging via a BMS.