Can I Charge a 14.4V Battery with a 12V Charger?

Charging a 14.4V battery with a 12V charger is generally not recommended because the lower voltage charger cannot adequately reach the battery’s full charge voltage, leading to incomplete charging, reduced battery life, and potential damage. Proper voltage matching is critical for safe, efficient charging and to extend battery longevity.

Why is voltage compatibility crucial when charging batteries?

Voltage compatibility ensures that the charger can supply sufficient force to push current into the battery and bring it to full charge. Charging a 14.4V battery with only 12V means the charger cannot reach the required voltage for full saturation, resulting in an incomplete charge that compromises battery performance and lifespan. Proper voltage matching is paramount to prevent inefficiencies and damage.

How does charging a 14.4V battery with a 12V charger affect battery performance?

Using a 12V charger on a 14.4V battery causes the battery to remain undercharged because the charger’s voltage falls short of the battery’s required charge voltage threshold. This leads to reduced capacity utilization, shorter run-times, and accelerated degradation, as frequent partial charges strain battery chemistry and contribute to premature aging.

What risks are associated with mismatched voltages during charging?

Charging mismatched voltages can cause multiple hazards:

- Incomplete charging, resulting in poor battery health.

- Overheating due to the battery drawing excessive current to compensate.

- Potential damage to the charger’s circuitry attempting to maintain current flow.

- Accelerated capacity loss and shortened lifespan of the battery.

Can a 12V charger deliver enough current to charge a 14.4V battery safely?

A 12V charger lacks the electrical potential difference required and thus cannot push adequate current into a 14.4V battery. The charger may run indefinitely without fully charging the battery, or the battery may draw more current, risking overheating. Safe, efficient charging demands a charger capable of reaching or exceeding the battery’s nominal voltage.

How do charging voltages relate to battery chemistries like Lead-Acid or Lithium?

Voltage requirements differ by chemistry: for instance, lead-acid batteries typically charge at 14.4V (2.4V per cell), while lithium-ion or LiFePO4 batteries have more specific charging profiles, sometimes requiring up to 16.8V for full charge. Using the correct charger aligned with the battery chemistry is vital. Mismatched voltages jeopardize safety and performance, emphasizing tailored charging approaches.

What limitations arise when using a 12V charger on a 14.4V battery?

The 12V charger will charge the battery very slowly, if at all, making the process inefficient and potentially incomplete. This causes longer charge cycles and stresses battery cells through partial charging patterns, impeding longevity and availability of full capacity. Additionally, incorrect charging can void warranties and possibly cause safety issues.

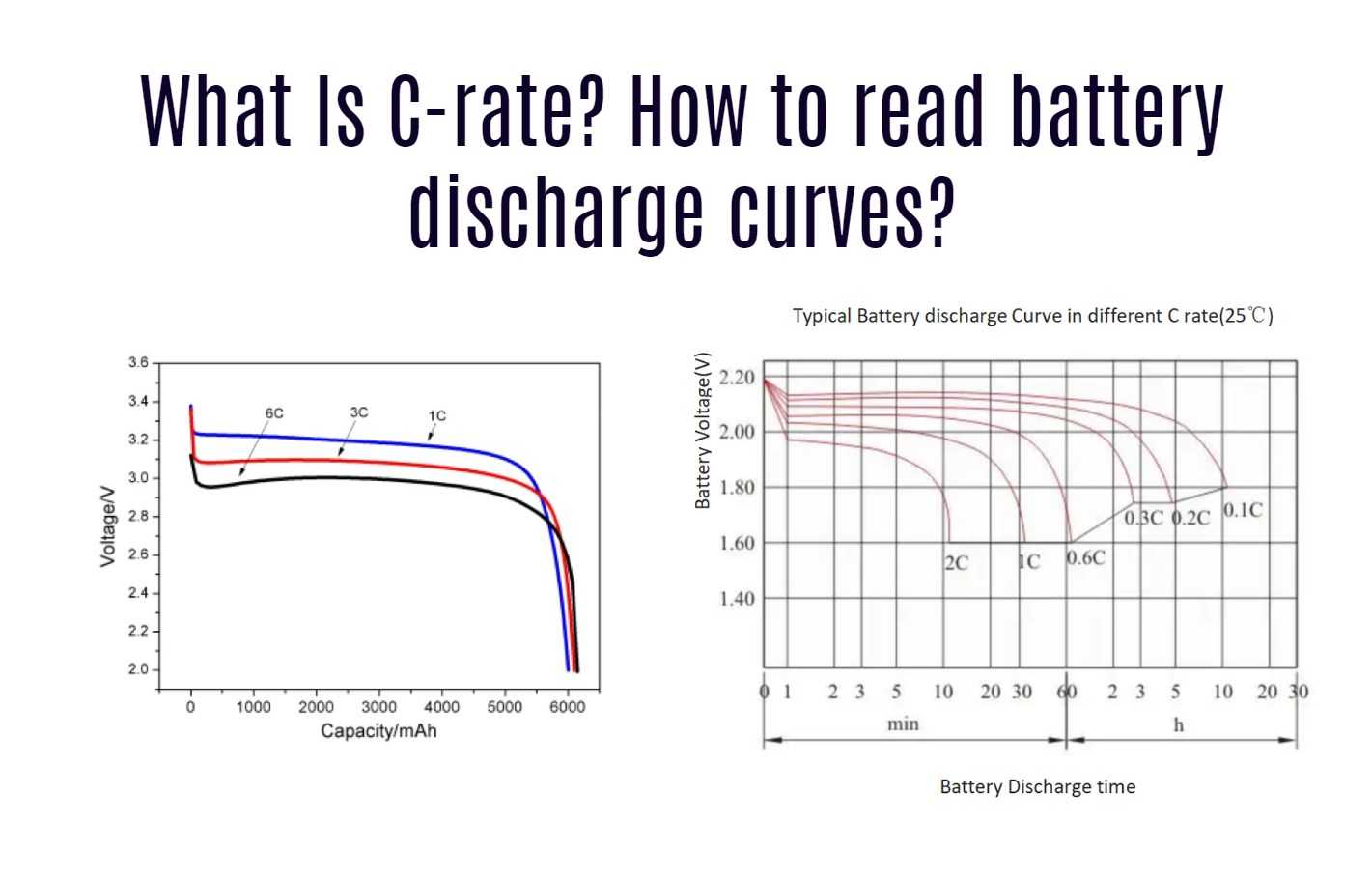

Chart: Charger Voltage vs Battery Compatibility

| Battery Nominal Voltage | Required Charging Voltage Range | Is 12V Charger Suitable? |

|---|---|---|

| 12V Lead-Acid | 13.8V – 14.4V | Yes |

| 14.4V Lead-Acid/Li-ion | 14.0V – 16.8V | No |

| 14.8V Li-ion | 14.6V – 16.8V | No |

Can a battery’s internal management system (BMS) compensate for a lower voltage charger?

Battery Management Systems regulate cell balancing and prevent overcharge or deep discharge but cannot force the battery to accept a charge voltage it doesn’t receive from the charger. If the charger voltage is insufficient, the BMS cannot resolve undercharging; proper charger specification is essential.

What are the best practices for charging 14.4V batteries?

Always use a charger specifically designed for the battery’s nominal voltage and chemistry. For 14.4V batteries, a charger capable of providing around 14.4V to 16.8V with appropriate current control and multi-stage charging profiles ensures full, safe charges that maximize battery life and efficiency.

How does Redway Battery recommend charging 14.4V batteries for optimum performance?

Redway Battery emphasizes using smart chargers tailored to the battery chemistry, whether lithium-ion or lead-acid, with adjustable voltage and current parameters. Their lithium battery solutions come with integrated Battery Management Systems, optimizing charge cycles, maintaining proper voltage, and protecting against overcharge to dramatically enhance longevity.

Does charging a 14.4V battery with a 12V charger void warranties or cause damage?

Using an incompatible charger can void manufacturer warranties and lead to irreversible battery damage from chronic undercharging or overheating. It is both a safety and economic risk to use non-recommended chargers, underscoring the critical nature of voltage matching.

Redway Battery Expert Views

“Charging batteries with voltage mismatches is a common oversight with serious consequences. At Redway Battery, we focus on delivering lithium energy solutions engineered with built-in protections and intelligent charging requirements. Using a 12V charger on a 14.4V battery not only risks damaging the battery but also wastes time and efficiency. Proper charger selection aligned with battery specifications is fundamental to harnessing the full potential of modern lithium batteries and sustaining their performance over thousands of cycles.”

— Expert, Redway Battery

Conclusion

Charging a 14.4V battery with a 12V charger is inefficient and potentially damaging due to insufficient voltage to bring the battery to full charge. Using the correct charger that matches the battery voltage and chemistry is vital for safety, performance, and longevity. Redway Battery’s intelligent lithium solutions exemplify how precision charging maximizes battery lifespan and reliability, making proper charger-battery pairing indispensable.

FAQs

Q: Can I fully charge a 14.4V battery with a 12V charger?

A: No, a 12V charger cannot provide sufficient voltage to fully charge a 14.4V battery, resulting in incomplete charges.

Q: What happens if I use a 12V charger on a 14.4V lithium battery regularly?

A: Repeated undercharging can reduce battery capacity, cause overheating, and ultimately shorten battery lifespan.

Q: Is it safe to charge a 14.4V battery with a 12V trickle charger?

A: While trickle charging at low currents might not immediately damage the battery, it will still not fully charge it and is generally not recommended.

Q: How do I know which charger is suitable for my 14.4V battery?

A: Check the battery specifications for nominal and max charging voltages and select a charger designed to meet or slightly exceed those values with appropriate current limits.

Q: Does Redway Battery offer chargers compatible with 14.4V batteries?

A: Yes, Redway Battery supplies intelligent chargers optimized for their lithium batteries, ensuring safe, efficient, and long-lasting charging cycles.

Can I charge a large battery with a small charger?

Yes, a small charger can charge a large battery, but charging time will be much longer than usual. The charger must match the battery’s voltage and be appropriate for its chemistry. Using a charger with too low a current rating won’t harm the battery, but it will take many hours or even days to reach full charge, especially with high-capacity batteries.

Can you use a 12 volt charger for a different voltage battery?

No, using a 12 volt charger for batteries with a different voltage is not safe. Charged at a lower voltage, the battery may never reach full capacity. If the charger’s voltage is higher, it could damage the battery or cause dangerous conditions like overheating, leakage, or even explosion. Always match your charger’s voltage to the battery’s rated voltage.

Can a 12V charger charge a 15V device?

A 12V charger cannot properly charge a 15V device. The voltage is too low for correct operation, so the device’s battery will not charge efficiently, or may not charge at all. For safe and complete charging, always use a charger specified for your device’s required voltage.

Does charger voltage need to match battery voltage?

Yes, the charger voltage should closely match the battery voltage for proper and safe charging. Incorrect voltage can lead to undercharging, overcharging, reduced battery lifespan, or even serious safety hazards. Always check both the voltage and chemistry requirements before connecting a charger to a battery.