How to Access the Battery on a Toyota Forklift: A Complete Guide

Accessing the battery on a Toyota forklift involves locating the battery compartment, which is typically either under the operator’s seat or in the rear compartment, then safely removing any covers or panels for inspection or maintenance. Ensuring the forklift is turned off, the key removed, and wearing protective gear are critical steps for safe battery access.

Where is the battery located on a Toyota forklift?

Toyota forklift batteries are most commonly found in two locations depending on the model: under the operator’s seat or in the rear compartment. For example, models like the Toyota 7FBE house the battery beneath the seat, while others such as the Toyota 8FGCU have their battery located in the rear. Some heavy-duty models may place the battery beneath the floorboard. Always consult your forklift’s manual to verify your model’s exact battery placement.

| Forklift Model | Battery Location |

|---|---|

| Toyota 7FBE | Under operator’s seat |

| Toyota 8FGCU | Rear compartment |

| Toyota 4FD25 | Underneath the floorboard |

How do you safely prepare to access the battery on a Toyota forklift?

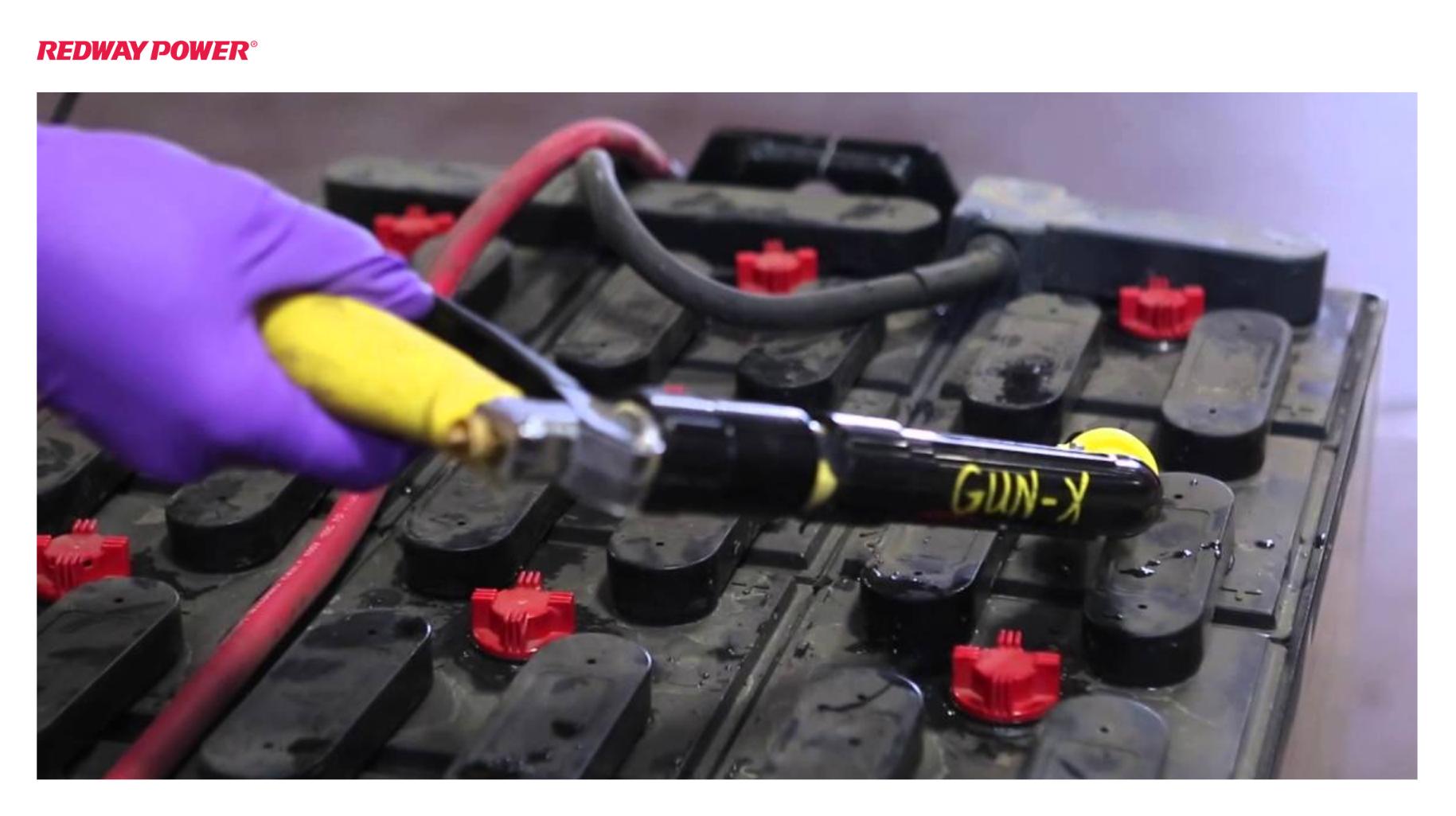

Safety preparation is essential before accessing the battery. First, ensure the forklift is completely powered down and the ignition key is removed to avoid accidental start-up. Then, wear appropriate personal protective equipment (PPE) such as gloves and safety goggles to protect against battery acid or electrical hazards. Finally, make sure no metal objects are near battery terminals to prevent sparks or shorts.

| Safety Measure | Description |

|---|---|

| Turn off forklift | Prevents accidental operation |

| Remove key | Ensures no power is supplied |

| Wear PPE | Protects against acid and sparks |

What tools are required to access the battery compartment?

To access the battery, simple hand tools like a screwdriver or wrench are typically required to remove any screws or bolts securing protective covers or panels. Always keep the right-sized tools handy, as some models may have uniquely fastened compartments to ensure safety and durability.

| Tool | Purpose |

|---|---|

| Screwdriver | Remove screws |

| Wrench | Loosen bolts |

How do you remove covers or panels to reach the battery?

Once you locate the battery compartment, remove any obstructing covers or panels by unscrewing or unfastening them using the appropriate tools. Carefully lift or slide the battery out depending on its mounting style, ensuring you maintain safe handling, especially given the battery’s weight and chemical content.

How should the battery be inspected once accessed?

After gaining access, inspect the battery for common issues. Look for corrosion indicated by white or greenish residue on terminals, cracks, leaks, or swelling in the casing. Also confirm that terminal connections are tight and clean to ensure optimal electrical contact and prevent voltage drops.

| Inspection Aspect | What to Look For |

|---|---|

| Corrosion | White or green buildup on terminals |

| Damage | Cracks, swelling, or leaking casing |

| Connections | Secure, clean terminal clamps |

How do you safely reassemble the battery compartment and test the forklift?

After maintenance or inspection, securely replace all covers or panels and tighten fasteners to restore the safety enclosure. Reinsert the ignition key, start the forklift, and perform a test run checking that the electrical system and power delivery function correctly and safely.

| Action | Description |

|---|---|

| Replace covers | Ensures operator safety |

| Test run | Confirms battery function |

How does the battery location design benefit Toyota forklifts?

Positioning the battery under the operator’s seat lowers the center of gravity, enhancing balance and stability during lifting operations. Rear compartment placement serves as an effective counterweight, improving equilibrium and maneuverability. These strategic designs facilitate easier access for maintenance while contributing to safe forklift operation.

What maintenance practices are recommended after accessing the battery?

Routine maintenance includes checking electrolyte levels (in lead-acid batteries), cleaning terminals to prevent corrosion, and verifying proper charging practices. Using distilled water to top off batteries after charging prevents damage. Maintaining charge between 30% and 80% state of charge preserves battery longevity. Lithium batteries from manufacturers like Redway Battery require less maintenance but still benefit from regular inspections.

How can Redway Battery technology improve forklift battery access and maintenance?

Redway Battery offers advanced lithium forklift batteries featuring integrated battery management systems (BMS) that simplify monitoring and maintenance. Their lighter weight and modular design streamline battery removal and installation, reducing downtime. These technologies enhance safety during battery access and optimize performance, particularly for Toyota forklift retrofit and replacement solutions.

What common issues warrant professional attention after battery access?

Common issues include persistent terminal corrosion, damaged casings, leakage, and battery overheating. If detected during inspection, these issues suggest replacement or professional servicing to avoid safety hazards and operational failures. Consulting the forklift’s manual or contacting battery experts, including Redway Battery, is advisable for complex problems.

| Issue | Potential Sign | Recommended Action |

|---|---|---|

| Corrosion | Residue buildup | Clean terminals, inspect seals |

| Physical damage | Cracks, leaks | Replace battery |

| Overheating | Excessive warmth | Service or replace battery |

How often should forklift batteries be accessed for inspection?

Regular battery inspection is recommended monthly or after every 100 operational hours. For lithium batteries such as those from Redway Battery, monitoring via software-enabled BMS can reduce physical inspection frequency but periodic visual checks remain crucial for safety.

{start chart}

Battery Inspection Frequency Recommendations

| Battery Type | Inspection Interval |

|---|---|

| Lead-Acid (Standard) | Monthly or 100 operation hours |

| Lithium (Redway Battery) | As per BMS monitoring, visual check every 3 months |

{end chart}

Redway Battery Expert Views

“Accessing and maintaining forklift batteries safely is essential for preserving operational efficiency and lifespan,” notes Wei Chen, senior engineer at Redway Battery. “Our lithium batteries simplify many traditional maintenance challenges by integrating intelligent battery management, enhancing accessibility and safety. However, operators must always adhere to safety procedures and routine inspections to ensure optimal performance and longevity.”

Conclusion

Accessing the battery on a Toyota forklift demands careful attention to model-specific battery locations, safety precautions, and correct use of tools to remove protective covers. Proper inspection and maintenance afterward significantly improve battery health and forklift performance. Innovations from Redway Battery bring advanced lithium technology solutions simplifying battery handling and raising operational safety and efficiency. Following this comprehensive guide ensures safe, effective battery access and care, safeguarding your Toyota forklift’s power system longevity.

FAQs

Q1: Where exactly is the battery located on a Toyota forklift?

It is usually located under the operator’s seat or in the rear compartment, depending on the model.

Q2: What safety gear should I use when accessing the forklift battery?

Always wear gloves and safety goggles to protect against battery acid and electrical hazards.

Q3: What tools do I need to access the battery?

A screwdriver and wrench are commonly needed to remove screws or bolts securing battery covers.

Q4: How often should I inspect my forklift battery?

Lead-acid batteries should be inspected monthly or every 100 hours of operation; lithium batteries can be monitored using BMS with less frequent visual inspections.

Q5: How does Redway Battery improve forklift battery maintenance?

Redway Battery’s lithium technology with integrated BMS reduces maintenance needs, improves safety during access, and enhances battery lifespan.

Where is the battery on a Toyota forklift?

The battery on a Toyota forklift is typically located under the operator seat or the battery compartment hood. For electric models, it may be accessed by lifting the seat or rear cover. Always ensure the forklift is turned off before opening the battery compartment.

Where is the battery located on a Toyota?

In a Toyota vehicle, the battery is usually located under the hood, near the front of the engine bay, either on the left or right side depending on the model. Some hybrids may have an auxiliary battery in the trunk or rear seat area.

How do you jump start a Toyota forklift battery?

To jump start a Toyota forklift, use jumper cables and a battery with matching voltage. Connect the positive terminals first, then the negative. Start the donor vehicle or battery source, then try the forklift. Avoid jump-starting a damaged or leaking battery, and wear safety gear.

How do you maintain a Toyota forklift battery?

To maintain a Toyota forklift battery, check fluid levels weekly (for lead-acid), clean terminals, and inspect for corrosion or leaks. Charge only when battery cools to room temperature and avoid deep discharges. For lithium models, ensure regular software updates and visual inspections for optimal health.