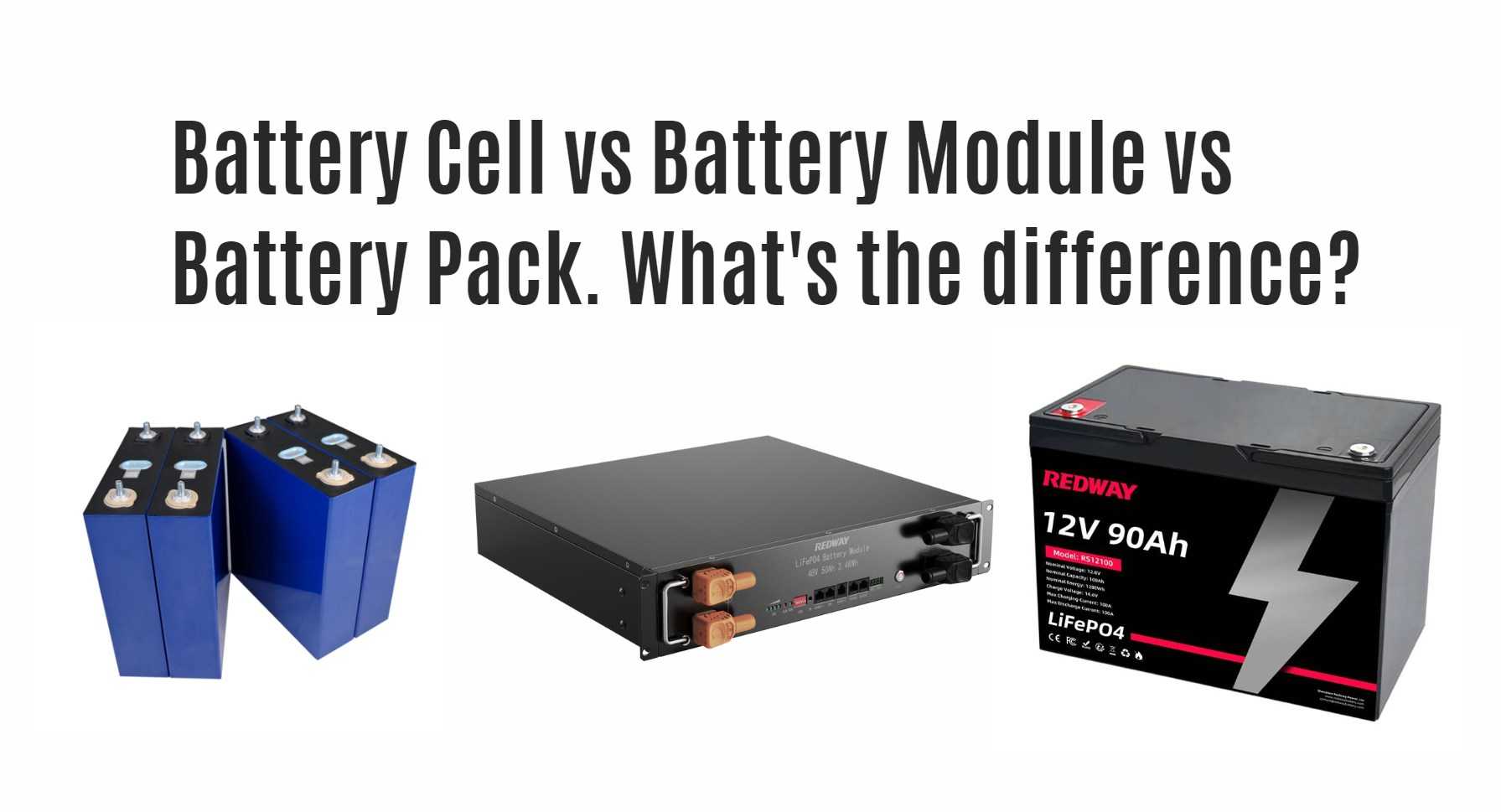

Battery cells are the fundamental units containing electrochemical components, modules group multiple cells for enhanced voltage or capacity, and battery packs assemble modules with management systems into complete, ready-to-use power sources. Understanding these distinctions helps optimize energy solutions across industries.

What Is a Battery Cell and How Does It Work?

A battery cell is the smallest unit of a battery and contains an anode, cathode, separator, and electrolyte to store and release electrical energy through chemical reactions.

Each cell converts chemical energy into electrical energy using specific chemistries like LiFePO4 or lithium-ion. The cell’s performance, capacity, and voltage define its utility. For instance, Redway Battery manufactures high-quality LiFePO4 cells offering stability, safety, and long cycle life, suitable for demanding industrial and recreational applications.

How Is a Battery Module Different From a Single Cell?

A battery module is a collection of multiple battery cells connected in series or parallel to increase overall voltage and capacity, and it often includes basic safety components.

Modules standardize cells into manageable units that enhance scalability and simplify manufacturing and maintenance. Modules from Redway Battery incorporate integrated wiring, thermal management, and fusing to improve reliability and performance within larger battery packs, bridging the gap between cells and packs.

What Comprises a Battery Pack and Why Is It Important?

A battery pack consists of several battery modules assembled with battery management systems (BMS), cooling, structural frames, and protective enclosures to provide safe, efficient, ready-to-use power.

Packs are engineered systems delivering optimized power output, longevity, and safety for end-use devices like forklifts or golf carts. Redway Battery’s packs feature ISO-certified manufacturing and advanced MES controlled assembly to ensure consistent quality and customizable solutions across applications such as telecom and energy storage.

| Component |

Function |

Examples |

| Battery Cell |

Basic electrochemical unit |

LiFePO4 cylindrical cell |

| Battery Module |

Group of cells with safety & wiring integration |

4S2P LiFePO4 module |

| Battery Pack |

Assembly of modules + BMS + cooling + housing |

Forklift battery pack with BMS |

Why Does Battery Management System (BMS) Matter in Battery Packs?

BMS monitors voltage, current, temperature, and state of charge, protecting cells from overcharge, discharge, and thermal risks, thereby enhancing safety and lifespan.

Without a BMS, individual cells may become unbalanced, leading to reduced capacity, safety hazards, or premature failure. Redway Battery integrates advanced BMS in their packs to ensure real-time monitoring and fault prevention across all modules and cells, critical in applications such as RVs or solar energy systems.

How Do Battery Cells, Modules, and Packs Impact Performance and Scalability?

Cells’ chemistry determines baseline capacity and voltage; modules scale capacity or voltage through cell grouping; packs integrate modules with management systems to customize capacity, voltage, and safety for specific applications.

This layered construction enables scalable designs—from single-cell devices to large energy storage systems—offering flexibility tailored for forklifts, telecom, or playground energy needs. Redway Battery’s production lines allow precise customization at each level, providing clients scalable solutions that meet diverse performance and safety requirements globally.

When Should You Choose a Custom Battery Module or Pack?

Customization is essential when standard cells or packs do not meet unique voltage, capacity, shape, or thermal needs, such as in specialized industrial equipment or custom electric vehicles.

Redway Battery’s engineering team supports full OEM/ODM customization, adjusting cell arrangements, pack enclosures, and BMS functions to fit client specifications for enhanced efficiency, safety, and durability.

Are Lithium Cells Always Used in Modern Battery Packs?

Most modern packs use lithium-based cells like LiFePO4 due to their increased energy density, safety, and cycle life compared to traditional chemistries such as lead-acid.

Redway Battery specializes in LiFePO4 technology, combining high performance with environmental friendliness, making them ideal for a wide range of sectors, including playground equipment and golf carts.

How Does Thermal Management Differ Between Cells, Modules, and Packs?

Cells generate heat during charge and discharge; modules incorporate cooling channels or plates; packs include active or passive thermal systems to maintain safe operating temperatures.

Managing heat is vital for reliability and longevity. Redway Battery’s packs use advanced thermal design within modules and pack structures to mitigate hotspots and enhance safety across usage conditions.

Where Are Battery Cells, Modules, and Packs Commonly Used?

Cells are built into modules and packs used across electric vehicles, renewable energy, telecom backup, forklifts, and recreational machinery.

Each layer plays a role: cells provide core units, modules offer scalable blocks, and packs deliver integrated systems tailored to end-use. Redway Battery serves diverse markets globally by providing every level from cells to fully assembled packs.

Redway Expert Views

“At Redway Battery, our expertise extends across the whole battery stack—from base cells to customized modules and complete packs. We understand that each layer must be engineered for performance, safety, and reliability to power the next generation of playground and industrial equipment. Leveraging advanced LiFePO4 chemistry and precise manufacturing, we deliver energy storage solutions that are not only powerful and durable but also easy to integrate and maintain, pushing the boundaries of what modern battery technology can achieve.” — Redway Battery Engineering Team

Conclusion

Understanding the differences between battery cells, modules, and packs is essential for selecting, designing, or replacing energy storage systems. Cells are electrochemical sources; modules group cells for flexibility; packs integrate modules with management and safety components. Companies like Redway Battery provide industry-leading solutions across all levels, ensuring high performance, durability, and customization for various industries.

FAQs

Q1: Can a battery pack work without a BMS?

No, a BMS is critical for safety, monitoring, and balancing cells to prevent damage and hazards.

Q2: How many cells are typically in a battery module?

Modules vary but commonly contain 4 to 16 cells arranged for desired voltage and capacity.

Q3: Are battery modules interchangeable between different packs?

Modules are often application-specific due to wiring, size, and BMS compatibility.

Q4: What advantages do LiFePO4 cells bring to battery packs?

They offer higher safety, longer cycle life, better thermal stability, and environmental benefits.

Q5: How does Redway Battery ensure quality across cells, modules, and packs?

Through ISO 9001:2015 certification, automated MES production, and rigorous testing protocols.