Welcome to our comprehensive guide on heated batteries for Original Equipment Manufacturer (OEM) applications. We pride ourselves on providing state-of-the-art solutions that enhance reliability and performance in cold weather conditions. Our dedication to innovation and customization ensures that each product is tailored to meet the specific needs of our OEM partners.

Understanding Heated Batteries: A Technological Breakthrough

Heated batteries, especially those utilizing LiFePO4 chemistry, mark a significant leap forward from traditional lead-acid batteries. Their standout feature is exceptional energy density, which enables greater energy storage in a compact package. This attribute renders them highly suitable for applications that demand consistent performance in cold climates.

Applications of Heated Batteries

Heated batteries are extensively utilized across various sectors where dependable performance in extreme cold is essential:

- Outdoor Equipment: Such as snowmobiles, ATVs, and snow blowers.

- Electric Vehicles and Drones: To ensure continuous operation in harsh weather conditions.

- Aerospace and Military: For powering vital equipment like communication systems and cockpit instruments.

Customization Options for Tailored Solutions

Customization is central to our approach at [Your Company Name]. We provide a broad spectrum of options to customize heated batteries to meet precise OEM specifications:

- Size and Shape: Tailored dimensions for a perfect fit within your product design.

- Capacity: Energy storage solutions that match the exact requirements of your application.

- Heating Element and Insulation: Designed for optimal thermal management and efficiency.

- Connectors and Wiring: Ensured for a smooth connection with your existing infrastructure.

Charging Flexibility and Efficiency

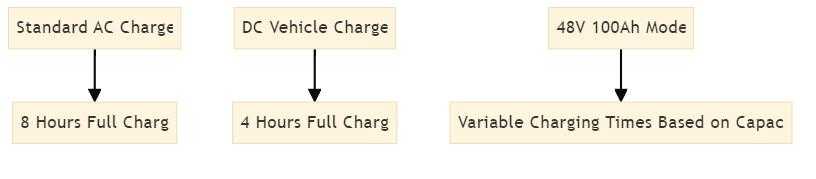

This diagram illustrates the charging options available for heated batteries, including standard AC chargers for an 8-hour full charge and DC vehicle chargers that can achieve a full charge in 4 hours. Additionally, the charging times for different battery models, such as a 48V 100Ah, are variable and based on their capacity.

Safety Features for Peace of Mind

Safety is paramount with our heated batteries. They incorporate advanced features such as:

- Battery Management System (BMS): Monitors temperature and prevents overheating.

- Protection Mechanisms: Including overcharge, over-discharge, short circuit, and over-temperature safeguards.

- Durable Design: Built to withstand impact, vibration, and harsh environmental conditions.

Technical Support and Expert Guidance

We provide comprehensive technical support to ensure seamless integration of our heated batteries into your products:

- Engineering Expertise: Assistance in system design and optimization.

- Testing and Certification: Ensuring compliance with stringent industry standards.

- Protocols and Best Practices: Guidance on optimal charging methods for longevity and performance.

Conclusion

In conclusion, Redway sets the benchmark for heated battery solutions, offering unmatched customization, reliability, and safety. Partner with us to elevate your products with cutting-edge battery technology designed for the toughest environments.

Tags: Heated Battery, OEM Applications