1. Overview of Lithium Iron Phosphate Batteries

1.1 What is LiFePO4?

LiFePO4 is a type of lithium-ion battery that uses lithium iron phosphate as the cathode material. This chemistry offers several advantages over traditional lithium-ion batteries, including:

-

Safety: LiFePO4 batteries are less prone to thermal runaway.

-

Long Cycle Life: They can withstand more charge-discharge cycles without significant capacity loss.

-

Environmental Impact: The materials used are less toxic compared to other lithium-ion chemistries.

1.2 Applications of LiFePO4 Batteries

LiFePO4 batteries are utilized in various applications:- Electric Vehicles (EVs): Due to their safety and longevity.

- Renewable Energy Storage: For solar and wind energy systems.

- Power Tools: Offering high discharge rates and durability.

2. Materials Required for Manufacturing LiFePO4 Batteries

2.1 Cathode Material

The primary component of LiFePO4 batteries is the cathode material:

-

Lithium Iron Phosphate (LiFePO4): This is synthesized from lithium carbonate and iron phosphate.

2.2 Anode Material

The anode typically consists of:

-

Graphite: Commonly used due to its excellent conductivity and stability.

2.3 Electrolyte

The electrolyte facilitates ion movement between the anode and cathode:

-

Lithium Salt Solution: Common salts include lithium hexafluorophosphate (LiPF6) dissolved in organic solvents.

2.4 Separator

A separator prevents short circuits while allowing ion flow:- Polyethylene or Polypropylene Films: These materials are commonly used for their insulating properties.

3. Manufacturing Process of LiFePO4 Batteries

3.1 Synthesis of Cathode Material

The first step involves synthesizing the LiFePO4 cathode material:

-

Chemical Reaction: Lithium carbonate and iron phosphate are mixed and heated at high temperatures (around 600–800°C) to form LiFePO4.

3.2 Preparation of Electrode Slurry

Next, a slurry is prepared for the electrodes:

-

Mixing Materials: The synthesized LiFePO4 powder is mixed with a binder (such as polyvinylidene fluoride) and conductive additives (like carbon black) in a solvent.

3.3 Coating the Electrodes

Once the slurry is prepared, it is coated onto current collectors:

-

Current Collectors: Typically made from aluminum for the cathode and copper for the anode.

-

The coated electrodes are dried to remove solvents.

3.4 Cutting and Pressing

After drying, the electrodes are cut into appropriate sizes:

-

Pressing: The electrodes are then pressed to enhance density and improve electrical conductivity.

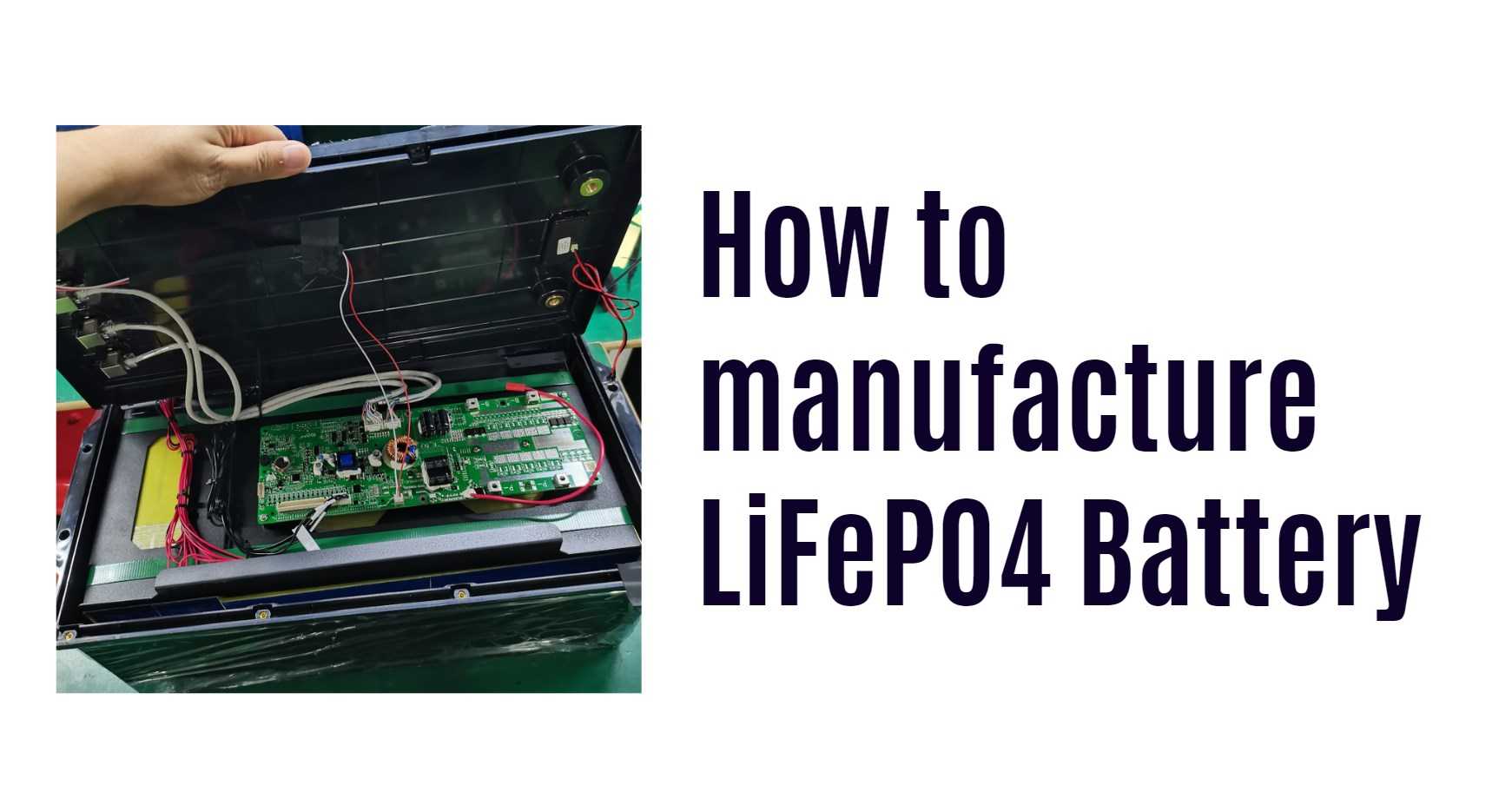

3.5 Assembly of Cells

The next step involves assembling the battery cells:

-

The anode, separator, electrolyte, and cathode layers are stacked or wound together in a specific configuration.

3.6 Sealing the Cells

The assembled cells must be sealed to prevent leakage:

-

Encapsulation: Cells are encapsulated in a protective casing that provides structural integrity and safety.

3.7 Formation Process

After sealing, the cells undergo a formation process:- This involves charging and discharging the cells several times to stabilize their capacity and performance characteristics.

4. Quality Control Measures

Quality control is critical throughout the manufacturing process to ensure optimal performance:- Testing Procedures: Each batch of materials should undergo rigorous testing for purity and consistency.

- Performance Testing: Finished cells must be tested for capacity, cycle life, and safety under various conditions.

| Quality Control Aspect | Methodology | Importance |

|---|---|---|

| Material Purity | Chemical analysis | Ensures optimal performance |

| Capacity Testing | Charge-discharge cycles | Validates energy storage capability |

| Safety Testing | Overcharge and short circuit tests | Prevents catastrophic failures |

5. Latest News in Lithium Iron Phosphate Battery Technology

Recent advancements in LiFePO4 technology focus on improving efficiency, reducing costs, and enhancing performance:- Researchers are exploring new synthesis methods that lower production costs while maintaining high-quality standards.

- Innovations in battery management systems (BMS) allow for better monitoring and optimization of battery performance in real-time.

6. Frequently Asked Questions (FAQs)

6.1 What is the lifespan of a LiFePO4 battery?

LiFePO4 batteries typically have a lifespan of 2000–5000 cycles depending on usage conditions.

6.2 Are LiFePO4 batteries safe?

Yes, they are considered one of the safest lithium-ion chemistries due to their thermal stability.

6.3 Can I use LiFePO4 batteries in electric vehicles?

Absolutely! They are widely used in electric vehicles due to their safety features and longevity.7. Conclusion

In conclusion, manufacturing Lithium Iron Phosphate (LiFePO4) batteries involves a detailed process that requires careful selection of materials, precise engineering techniques, and rigorous quality control measures. Understanding these aspects can help manufacturers produce high-quality batteries that meet diverse customer needs across various applications.At Redway Battery, we specialize in manufacturing high-quality Lithium LiFePO4 solutions tailored to meet diverse customer needs worldwide. With our extensive experience in this field, we provide custom solutions quickly for wholesale and OEM customers. For a quick quote or more information about our products, please contact us today!