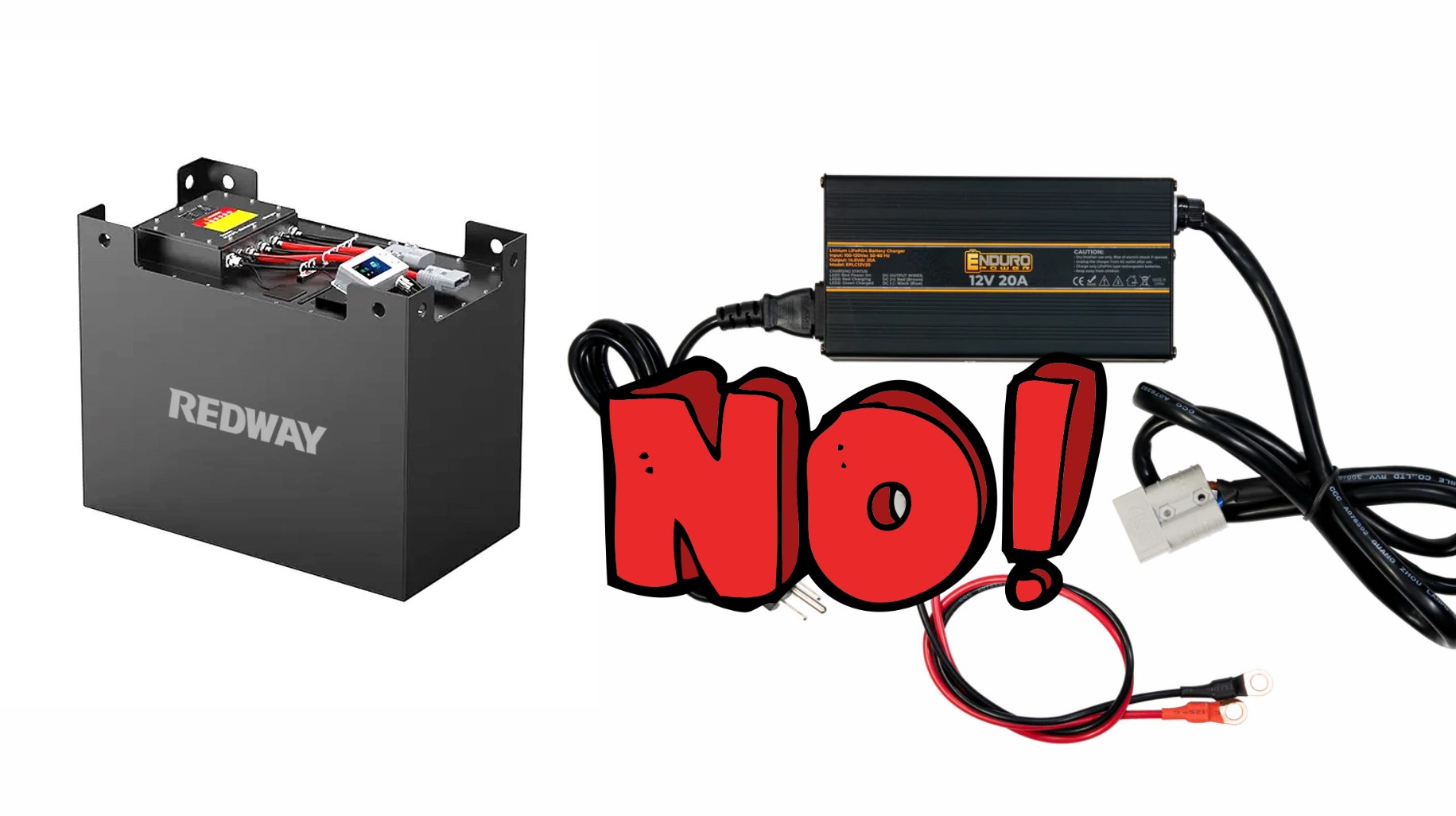

Charging a 36-volt forklift battery using a 12-volt charger is generally ineffective and potentially damaging because a 12-volt charger cannot supply sufficient voltage to fully charge a 36-volt system. Safe and efficient charging requires a charger matching the battery’s voltage—typically around 40 volts—to ensure balanced cell charging and preserve battery life.

Why Can’t You Charge a 36-Volt Forklift Battery with a 12-Volt Charger?

A 36-volt forklift battery usually consists of three 12-volt batteries connected in series, requiring a charging voltage around 40 volts to properly replenish all cells. A 12-volt charger outputs approximately 14 volts, which is insufficient to overcome the battery voltage for effective charging. Attempting to charge the entire 36V battery with 12V results in undercharging, battery damage, and reduced lifespan.

How Does Voltage Requirement Affect Forklift Battery Charging?

Effective charging requires a voltage higher than the battery’s nominal voltage to push current into the cells and complete the recharge cycle. For a 36V system, this means supplying roughly 40 volts to account for charging overhead. Chargers matched to voltage ensure each cell receives adequate current, which prevents imbalances and sulfation.

Wholesale lithium golf cart batteries with 10-year life? Check here.

Can You Use Multiple 12-Volt Chargers to Charge a 36-Volt Battery?

Technically, you can charge each 12-volt battery segment separately with individual 12-volt chargers simultaneously or in sequence. However, this approach is impractical and risky, as it requires careful monitoring to avoid uneven charging and potential overcharge of individual batteries. Redway Battery experts discourage this method due to complexity and increased likelihood of damage.

What Are the Risks of Undercharging a 36-Volt Forklift Battery?

Undercharging leads to incomplete electrolyte chemical reactions within battery cells, causing sulfation and capacity loss. Batteries maintained in a low charge state suffer reduced performance, shorter cycle life, and eventually premature failure. Using the correct voltage charger, like those recommended by Redway Battery, greatly reduces these risks.

Want OEM lithium forklift batteries at wholesale prices? Check here.

How Does a Proper 36-Volt Charger Work?

A proper 36-volt forklift battery charger delivers controlled voltage and current slightly above nominal battery voltage to enable full charging with safety protocols such as multi-stage charging and temperature compensation. It balances current flow through all battery cells to prevent damage and optimize battery health.

What Charging Configurations Are Recommended for 36-Volt Forklift Batteries?

Usually, 36V forklift batteries are charged with a single dedicated 36V charger designed for that battery type. For maintenance, trickle chargers specifically built for 36 volts can be used. Redway Battery’s charging solutions integrate smart technology to prolong battery life and ensure safe, efficient operation.

How Should You Maintain a 36-Volt Forklift Battery to Extend Its Lifespan?

Proper maintenance includes consistent full charging with an appropriate charger, monitoring electrolyte levels in flooded batteries, avoiding deep discharges, and storing batteries in temperature-controlled environments. Redway Battery recommends using matched charging systems and maintenance routines to maximize operational lifespan.

What Are the Signs Your 36-Volt Forklift Battery Needs Replacement or Service?

Indicators include reduced runtime, slow or incomplete charging, visible swelling or leakages, and failure to hold charge. When experiencing these symptoms, professional diagnostic and possible battery replacement, potentially with advanced lithium solutions offered by Redway Battery, may be necessary.

Charging Voltage and Battery Life Chart

| Charging Voltage | Battery Voltage System | Effectiveness |

|---|---|---|

| 12 volts | 36 volts | Ineffective, risks damage |

| 36 volts | 36 volts | Effective, recommended |

| Multiple 12 volts (in series) | 36 volts | Complex, risky, not recommended |

Redway Battery Expert Views

“Charging forklift batteries demands precision in voltage and current to ensure longevity and performance. Using a 12-volt charger on a 36-volt system risks undercharging and sulfation, prematurely degrading the battery. Redway Battery develops advanced charging systems designed to match exact battery specifications, promoting safety, efficiency, and extended operational life for industrial batteries.” — Redway Battery Specialist

Conclusion

Charging a 36-volt forklift battery with a 12-volt charger is not advisable due to mismatched voltage requirements, leading to undercharging and battery damage. The safest and most effective method is to use a dedicated 36-volt charger designed for forklift batteries, ensuring balanced, full charging cycles that preserve battery health. Redway Battery underscores the importance of proper charger selection and maintenance to extend battery life and maintain forklift performance.

FAQs

Can I charge a 36-volt forklift battery directly with a 12-volt charger?

No. A 12-volt charger cannot provide enough voltage to fully charge a 36-volt battery and may harm the battery.

Is it possible to use multiple 12-volt chargers to charge a 36-volt battery?

Technically yes, by charging each 12-volt battery individually, but it is complicated and not recommended due to risks of imbalance.

What voltage charger do I need for a 36-volt forklift battery?

A charger delivering approximately 36 to 40 volts, calibrated for forklift battery specifications, is necessary.

What happens if I undercharge my forklift battery?

Undercharging causes sulfation and battery capacity loss, eventually leading to premature battery failure.

Does Redway Battery provide suitable chargers for forklift batteries?

Yes, Redway Battery designs advanced, voltage-matched chargers that optimize battery health and efficiency for industrial equipment.