What Are Lithium Forklift Batteries?

Lithium forklift batteries are rechargeable power sources that use lithium-ion technology. They provide efficient and reliable energy for electric forklifts, offering advantages like faster charging and longer lifespan compared to traditional lead-acid batteries.

How Do Lithium Forklift Batteries Work?

Lithium forklift batteries work by storing energy in lithium-ion cells. When the battery is charged, lithium ions move from the positive electrode to the negative electrode. During use, these ions flow back, generating electricity to power the forklift.

What Are the Advantages of Lithium Forklift Batteries?

Lithium forklift batteries offer several advantages: they charge quickly (often in under two hours), have a longer lifespan (2,000-3,000 cycles), require less maintenance, and operate efficiently in various temperatures, making them ideal for busy warehouses.

The benefits include:

- Longer lifespan, typically lasting 2-3 times longer than lead-acid batteries.

- Faster charging times, allowing for opportunity charging during breaks.

- Reduced maintenance requirements since they do not need watering or equalization.

How to Maintain Lithium Forklift Batteries?

To maintain lithium forklift batteries, keep them clean and dry, avoid extreme temperatures, and ensure they are charged regularly. Unlike lead-acid batteries, they don’t require water refilling or equalization charges.

Maintenance is minimal due to their design; however, it includes:

- Regularly checking the battery management system for alerts.

- Ensuring proper ventilation during charging.

- Keeping the battery clean and free from debris.

What Types of Lithium Forklift Batteries Are Available?

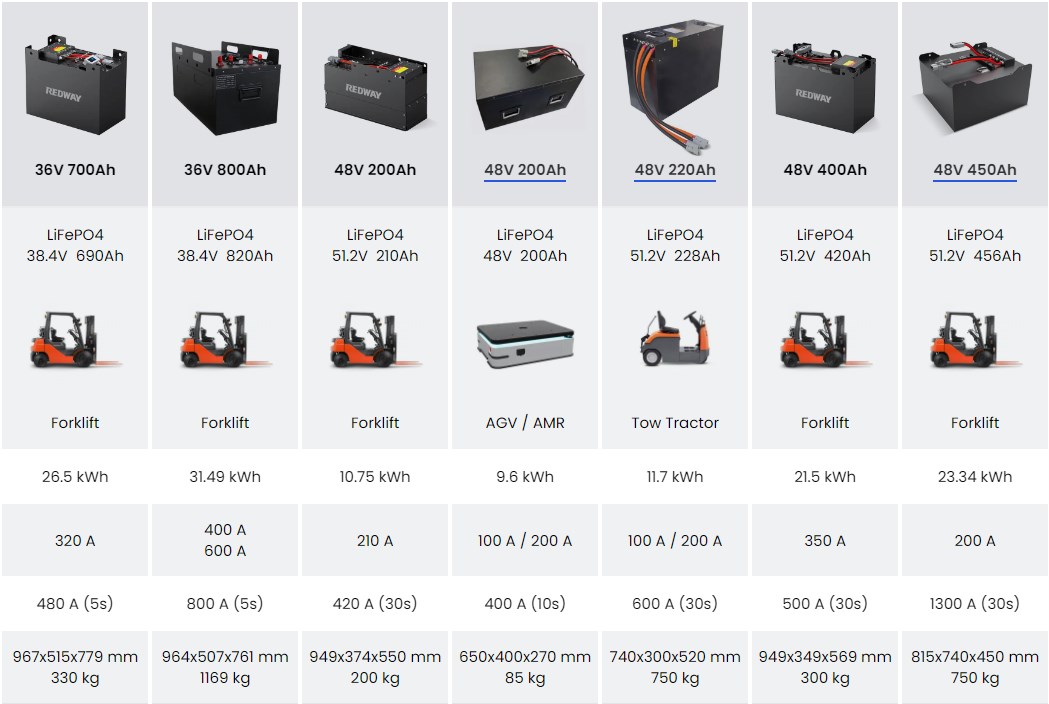

There are several types of lithium forklift batteries available, including lithium iron phosphate (LiFePO4) and lithium nickel manganese cobalt (NMC). Each type has unique characteristics suited for different applications and performance needs.

Various types include:

- Lithium Iron Phosphate (LiFePO4): Known for thermal stability and safety.

- Lithium Nickel Manganese Cobalt (NMC): Offers high energy density suitable for demanding applications.

Know More:

What Are Lithium Forklift Batteries?

What Are Used Forklift Batteries?

What Are Reconditioned Forklift Batteries?

How Can You Effectively Recondition a Forklift Battery?

What Is a Forklift Battery Pack?

How to Choose the Right Lithium Forklift Battery?

To choose the right lithium forklift battery, consider factors like the forklift’s power requirements, operating environment, charging speed, and expected usage hours. Ensure compatibility with your equipment for optimal performance.

Consider factors such as:

- Compatibility with your forklift model.

- Amp-hour ratings based on operational needs.

- Charging infrastructure available in your facility.

What Are Common Applications for Lithium Forklift Batteries?

Common applications for lithium forklift batteries include warehouses, distribution centers, manufacturing facilities, and retail spaces. They are ideal for operations requiring frequent lifting and quick recharging.

These batteries are widely used in:

- Warehousing

- Manufacturing

- Retail environments

They enhance productivity by allowing forklifts to operate efficiently over extended periods.

How Do Lithium Forklift Batteries Compare to Lead-Acid Batteries?

Lithium forklift batteries outperform lead-acid batteries in several ways: they charge faster, last longer (up to 10 years), require less maintenance, and provide consistent power output throughout their discharge cycle.

What Is the Lifespan of a Lithium Forklift Battery?

The lifespan of a lithium forklift battery typically ranges from 7 to 10 years or about 2,000 to 3,000 charging cycles. This longevity makes them a cost-effective choice for businesses over time.

How Do Environmental Conditions Affect Lithium Battery Performance?

Environmental conditions can impact lithium battery performance. Extreme temperatures can reduce efficiency; ideally, they should be used in environments between 32°F and 113°F (0°C to 45°C) for optimal operation.

What Safety Measures Should Be Taken When Handling Lithium Forklift Batteries?

When handling lithium forklift batteries, wear protective gear like gloves and goggles. Store them in a cool, dry place away from flammable materials. Follow manufacturer guidelines for charging and maintenance to ensure safety.

Expert Views

“Investing in lithium forklift batteries is a game-changer for many operations,” states an expert from Redway. “Their efficiency and low maintenance requirements can lead to significant cost savings over time.”

Conclusion

In summary, lithium forklift batteries represent a significant advancement in power solutions for electric forklifts, providing reliable energy with numerous operational benefits. Understanding their advantages, maintenance needs, and safety measures will help users maximize their investment in these critical power sources.

FAQ Section

- What is the average lifespan of a lithium forklift battery?

Typically ranges from 10 to 15 years or around 3,000 cycles with proper care. - How often should I charge my lithium forklift battery?

Charge regularly based on usage patterns; opportunity charging can be done during breaks. - Can I use a lead-acid charger on a lithium battery?

No, chargers must match the specific battery type due to differing charging requirements.