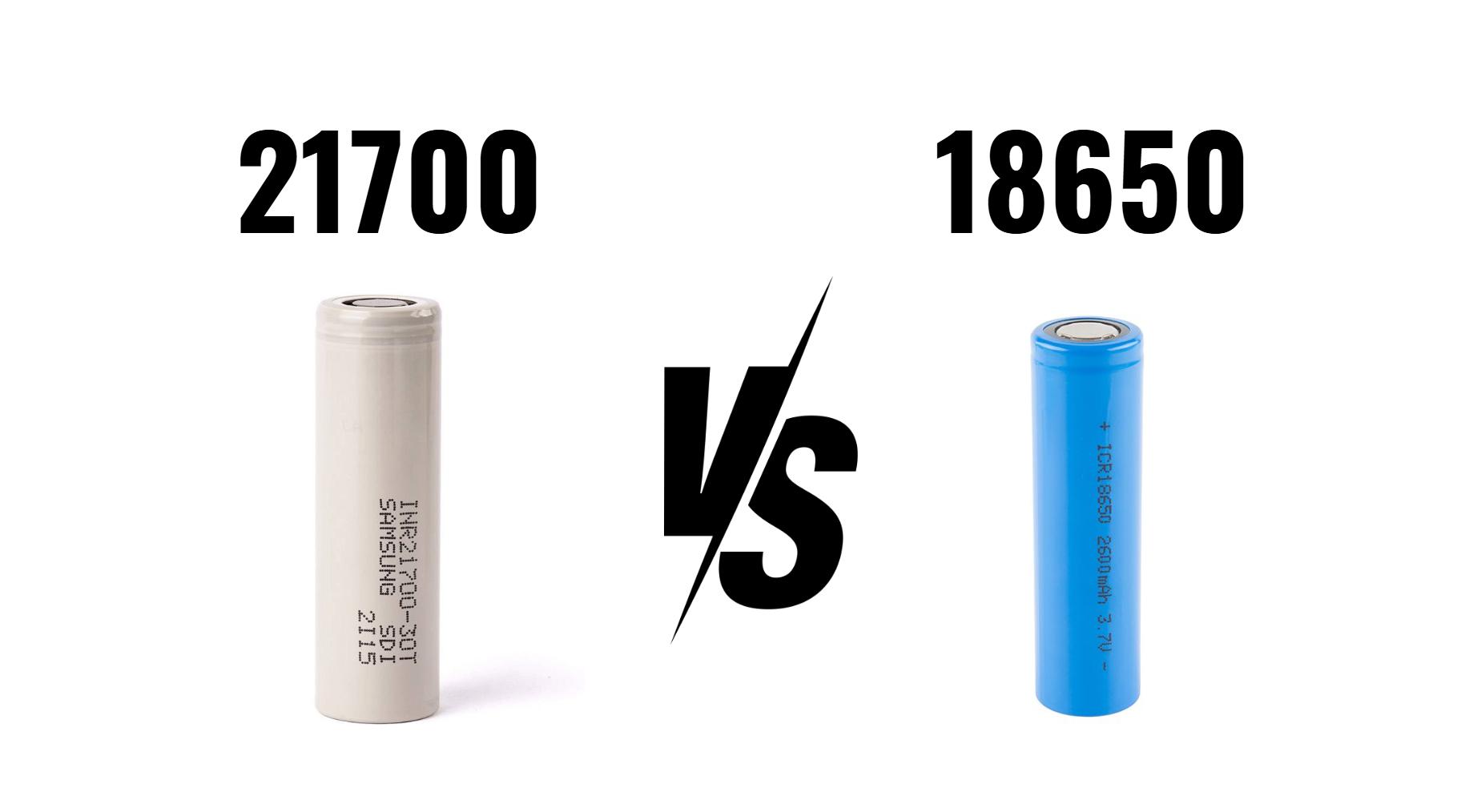

How Do 18650, 21700, and 26650 Batteries Compare?

The 18650, 21700, and 26650 batteries are popular lithium-ion battery types used in various applications. The 18650 typically has a nominal voltage of 3.7V and a capacity ranging from 1800mAh to 3500mAh, while the 21700 offers a slightly larger size with higher capacity (up to 5000mAh), and the 26650 boasts even greater capacity (up to 6000mAh). Understanding their differences helps in selecting the right battery for your needs.

Introduction to Battery Types

Lithium-ion batteries have become essential in powering modern devices, from laptops to electric vehicles. Among the various types available, the 18650, 21700, and 26650 batteries are widely recognized for their performance characteristics and versatility.

Overview of 18650, 21700, and 26650 Batteries

Each battery type has unique specifications that cater to different applications:

| Battery Type | Diameter | Length | Nominal Voltage | Typical Capacity |

|---|---|---|---|---|

| 18650 | 18 mm | 65 mm | 3.7V | 1800 mAh – 3500 mAh |

| 21700 | 21 mm | 70 mm | 3.7V | 3000 mAh – 5000 mAh |

| 26650 | 26 mm | 65 mm | 3.7V | 3200 mAh – 6000 mAh |

These specifications highlight the physical differences between the three battery types.

Size and Dimensions Comparison

The physical dimensions of these batteries significantly impact their applications:

- 18650: Measures approximately 18mm in diameter and 65mm in length, making it compact for various devices.

- 21700: Slightly larger at 21mm in diameter and 70mm in length, it strikes a balance between size and capacity.

- 26650: The largest of the three, measuring 26mm in diameter and 65mm in length, allowing for higher energy storage.

Size Implications:

| Feature | 18650 | 21700 | 26650 |

|---|---|---|---|

| Volume | Compact for portable devices | Good balance for power tools | Larger volume for high energy |

| Weight | Lighter due to smaller size | Moderate weight | Heavier due to larger size |

The choice between these sizes often depends on the specific requirements of the device being powered.

Voltage Ratings and Capacity

All three battery types operate at a nominal voltage of approximately 3.7 volts, but their capacities vary significantly:

- The 18650 battery generally offers capacities ranging from ***1800mAh to ***3500mAh.

- The 21700 battery, with its larger size, typically provides capacities between 3000mAh to 5000mAh.

- The 26650 battery can reach capacities up to 6000mAh due to its larger volume.

Capacity Comparison:

| Battery Type | Typical Capacity Range |

|---|---|

| 18650 | Up to 3500mAh |

| 21700 | Up to 5000mAh |

| 26650 | Up to 6000mAh |

This difference in capacity can influence performance based on how the batteries are used.

Performance Comparison

When it comes to performance, each battery type excels under different conditions:

- The 18650 battery is known for its versatility across various applications but may not sustain high power demands as effectively as larger batteries.

- The 21700 battery offers improved performance with higher discharge rates suitable for power-hungry devices.

- The 26650 battery, while providing substantial capacity, may have limitations regarding discharge rates compared to the more modern designs of the other two.

Performance Metrics:

| Metric | 18650 | 21700 | 26650 |

|---|---|---|---|

| Continuous Discharge | Typically lower than equivalent models due to size constraints | Higher discharge capabilities | Good capacity but lower discharge rates |

These performance characteristics make each battery suitable for different applications.

Advantages and Disadvantages of Each Type

Understanding the pros and cons can help users make informed decisions:

Advantages:

- 18650:

- High energy density.

- Versatile; fits many consumer electronics.

- 21700:

- Higher capacity than the 18650.

- Better thermal management with modern chemistries.

- 26650:

- Superior capacity for high-drain applications.

- Longer runtime for demanding devices.

Disadvantages:

- 18650:

- Lower maximum capacity compared to larger formats.

- 21700:

- Slightly bulkier than 18650; may not fit all devices.

- 26650:

- Larger size limits compatibility with many devices.

- Less common; fewer options available on the market.

Applications and Use Cases

Each battery type is suited for specific applications based on their characteristics:

Common Applications:

- 18650:

- Widely used in laptops, flashlights, vaping devices, electric bikes, and power tools.

- 21700:

- Increasingly found in electric vehicles (like Tesla), high-performance flashlights, laptops, and power banks due to its balance of size and capacity.

- 26650:

- Commonly used in high-drain devices such as electric vehicles, power tools, solar energy storage systems, and some specialized flashlights.

Application Chart:

| Application | Preferred Battery Type |

|---|---|

| High-performance flashlights | 26650 |

| Electric vehicles | 21700 |

| Power tools | Both (depending on design) |

This chart illustrates how each battery type fits into different market segments.

Future Trends in Battery Technology

As of November 2024, advancements in battery technology continue to focus on improving energy density, charging speeds, and sustainability. The industry is seeing increased adoption of the 21700 format due to its efficiency in electric vehicles and portable electronics. Research into solid-state batteries may also influence future designs, potentially offering even better performance metrics.

Latest News on Battery Developments

Recent developments indicate a growing trend towards adopting larger format cells like the 21700, particularly in electric vehicle manufacturing due to their higher energy density compared to older formats like the 18650 or even the larger 26650 cells. Innovations are also being made in recycling technologies aimed at reducing waste from lithium-ion batteries as environmental concerns rise.

Redway Expert Comment

Choosing between a 26650, 18650, or 21700 battery ultimately depends on your specific application needs,” says an expert from Redway Battery Solutions. “While all three offer excellent performance, understanding their differences can help you select the right one for optimal efficiency.”

Frequently Asked Questions (FAQs)

Are these batteries interchangeable?

No, these batteries are not interchangeable due to differences in size and specifications; always use the recommended battery type for your device.

What are the main advantages of using a 26650 over an 18650?

The primary advantage is its larger size allowing for higher capacity which is beneficial for high-drain applications where longer runtimes are needed.

Can I use a 21700 battery in devices designed for 18650 batteries?

It depends on your device’s design; ensure compatibility before substituting one for another as they differ significantly in size.

How do I know which battery type is best for my needs?

Consider factors such as device specifications (size constraints), required runtime (capacity), weight considerations (for portability), and cost-effectiveness based on your usage patterns.

Know more: