What Are the Key Components of a LiFePO4 Golf Cart Battery?

A lithium iron phosphate (LiFePO4) golf cart battery is a type of rechargeable battery specifically designed for use in electric golf carts, utilizing lithium iron phosphate as its cathode material. These batteries are known for their safety, longevity, and efficiency, making them an increasingly popular choice among golf cart users.

What Are the Key Components of a LiFePO4 Battery?

The key components of a LiFePO4 battery include:

- Cathode: Made from lithium iron phosphate (LiFePO4), it serves as the primary source of lithium ions during discharge.

- Anode: Typically composed of graphite, it stores lithium ions during charging.

- Electrolyte: A lithium salt solution that facilitates ion movement between electrodes.

- Separator: A porous membrane that prevents short-circuiting while allowing ions to pass through.

How Does Each Component Work?

The cathode stores lithium ions during charging, while the anode releases them during discharge. The electrolyte facilitates the movement of ions between the two electrodes, and the separator prevents short circuits while allowing ion transfer.

Each component plays a vital role:

- The cathode releases lithium ions during discharge, providing energy.

- The anode absorbs lithium ions during charging, storing energy for future use.

- The electrolyte enables ion transport while maintaining electrical neutrality.

- The separator ensures safe operation by preventing direct contact between electrodes.

What Are the Advantages of Using LiFePO4 Batteries in Golf Carts?

Advantages of LiFePO4 batteries in golf carts include longer lifespan (up to 6,000 cycles), faster charging times (1-4 hours), lighter weight, and enhanced safety compared to lead-acid batteries. They also provide consistent power output throughout their discharge cycle.

LiFePO4 batteries offer several advantages:

- Safety: They have high thermal stability and are less prone to overheating or combustion.

- Longevity: These batteries can last up to 3,000 cycles or more, significantly exceeding traditional lead-acid batteries.

- Efficiency: They provide higher energy density, allowing more energy storage in less space.

Know More:

What Are the Benefits of Using LiFePO4 Golf Cart Batteries?

What is the Chemistry Behind LiFePO4 Batteries?

LiFePO4 Batteries vs Lead-Acid Batteries for Golf Carts

What Are the Key Components of a LiFePO4 Golf Cart Battery?

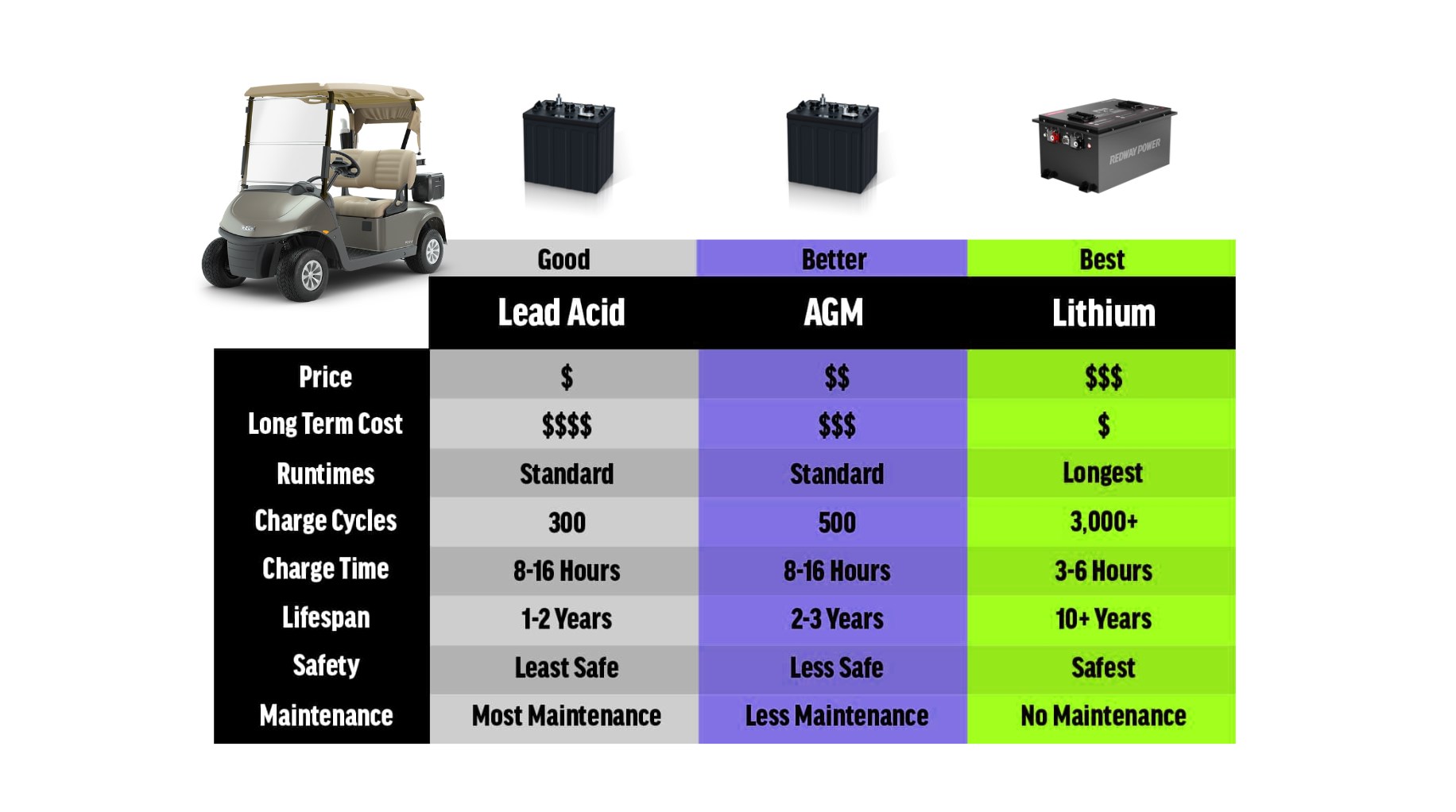

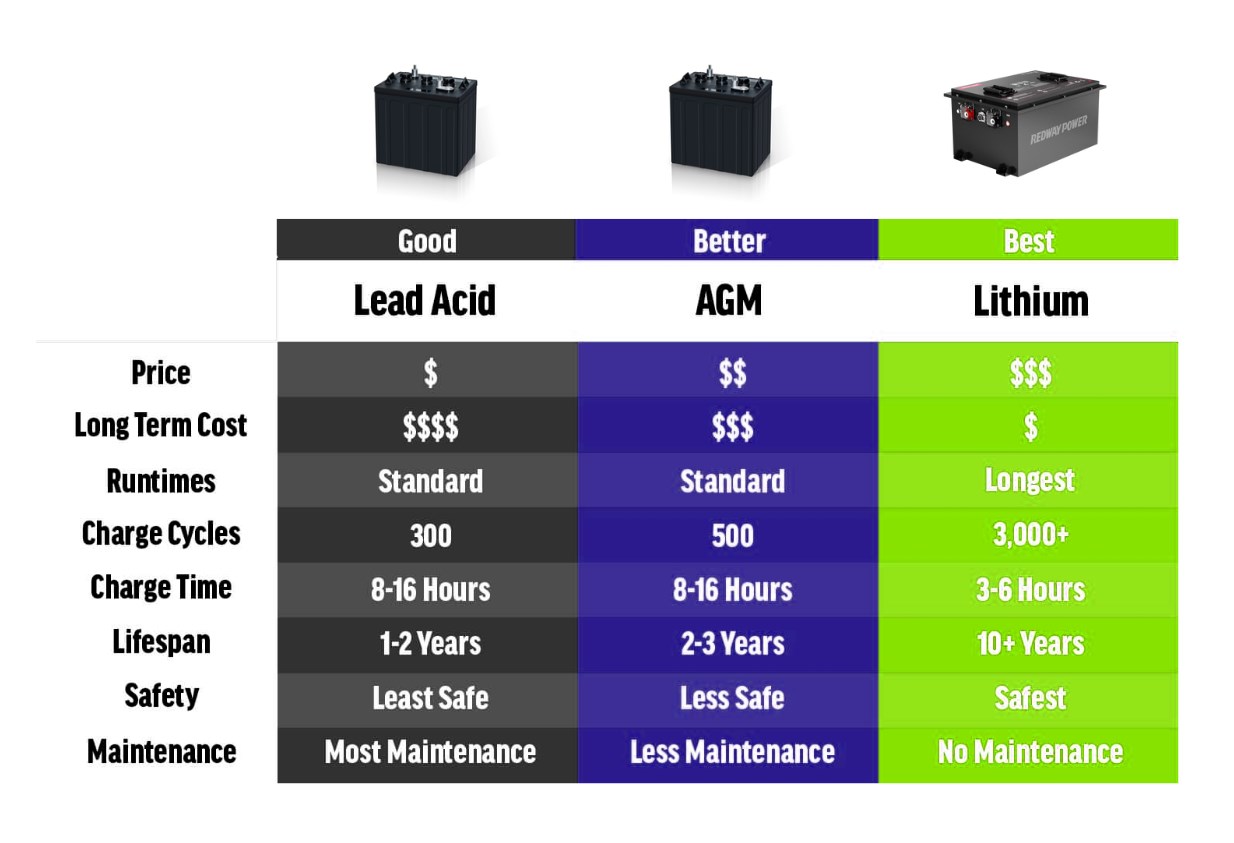

How Do LiFePO4 Batteries Compare to Lead-Acid Batteries?

LiFePO4 batteries outperform lead-acid batteries in several ways: they last longer (2,000-6,000 cycles), charge faster, are lighter, and require less maintenance. Lead-acid batteries typically last only 500-1,000 cycles and need regular watering.

Compared to lead-acid batteries, LiFePO4 batteries have several benefits:

- Longer lifespan and fewer replacements needed over time.

- Faster charging capabilities and lower self-discharge rates.

- Lighter weight, which improves overall vehicle efficiency.

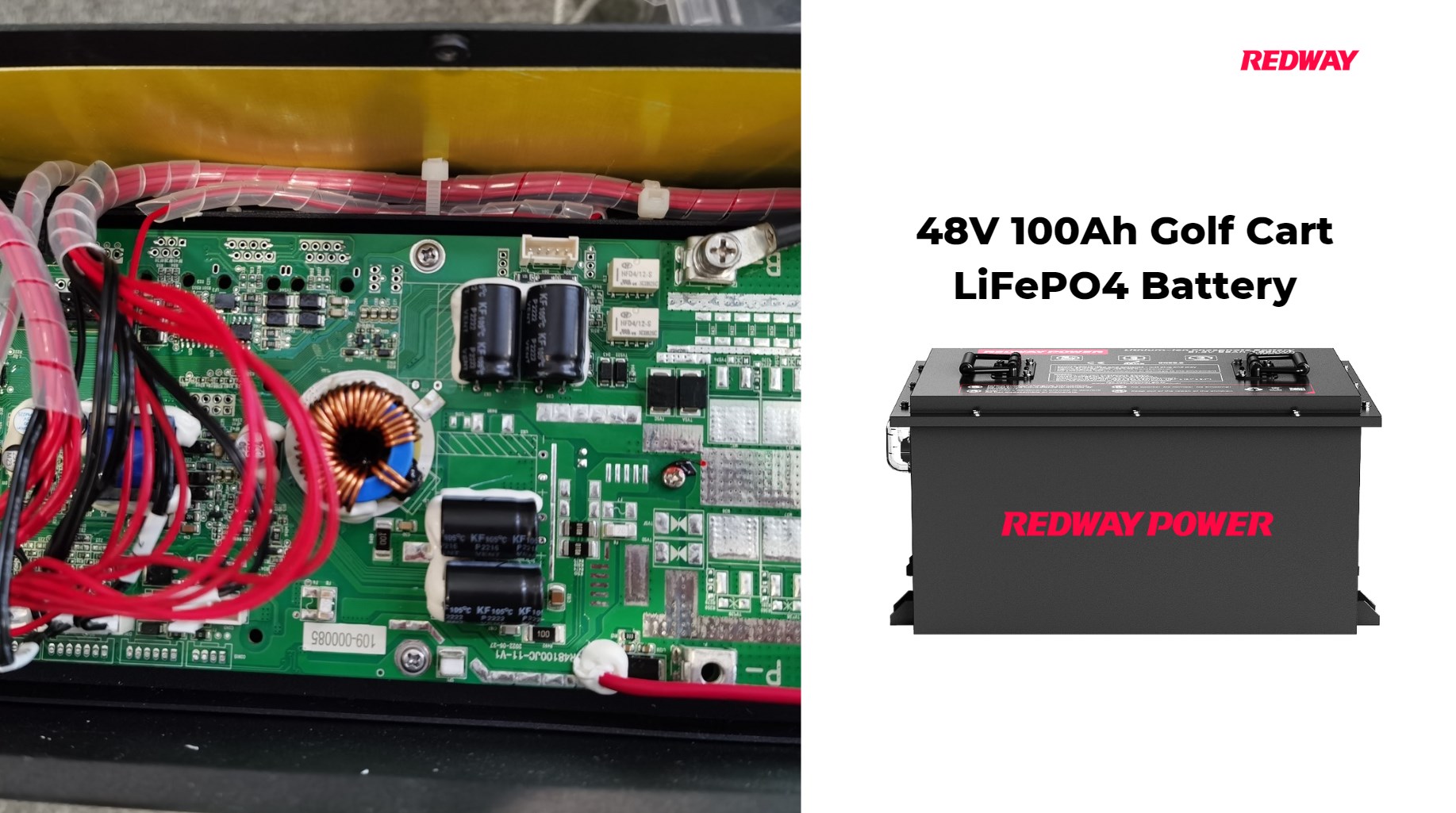

What Is the Role of the Battery Management System (BMS)?

The Battery Management System (BMS) monitors battery health by managing charge levels, balancing cells, and protecting against overcharging or overheating. It ensures safe operation and prolongs battery life.

- Overcharge and over-discharge protection.

- Temperature regulation to prevent overheating.

- Balancing charge levels across individual cells to enhance lifespan.

How Do Environmental Conditions Affect LiFePO4 Battery Performance?

Environmental factors such as temperature can significantly influence performance; while these batteries operate well in various conditions, extreme temperatures may affect their efficiency and lifespan. Proper management systems can help mitigate these effects.

What Maintenance Is Required for LiFePO4 Golf Cart Batteries?

Maintenance for LiFePO4 golf cart batteries includes regularly checking connections for corrosion, keeping the battery clean and dry, monitoring charge levels, and avoiding deep discharges to ensure optimal performance.

- Proper connections and corrosion at terminals.

- Monitoring charge cycles to avoid deep discharges.

- Keeping terminals clean and free from dirt or debris.

What Is the Lifespan of a LiFePO4 Golf Cart Battery?

The lifespan of a LiFePO4 golf cart battery typically ranges from 6 to 10 years or about 2,000 to 6,000 charge cycles. With proper care, they can provide reliable service for many years.

How Are LiFePO4 Batteries Manufactured for Golf Carts?

LiFePO4 batteries are manufactured by combining lithium iron phosphate with graphite in a controlled environment. The materials are processed into electrodes, assembled into cells, and integrated into battery packs with protective circuitry.

What Applications Are Best Suited for LiFePO4 Batteries Beyond Golf Carts?

Beyond golf carts, LiFePO4 batteries are well-suited for applications like electric vehicles, renewable energy storage systems, marine applications, and backup power supplies due to their safety, longevity, and efficiency.

- Electric vehicles

- Renewable energy storage systems

- Power tools

These applications benefit from their safety features and long cycle life.

Expert Views

“LiFePO4 batteries represent a significant advancement in energy storage technology,” states an expert from Redway. “Their unique properties make them particularly suitable for applications where safety and longevity are critical.”

Conclusion

In summary, understanding the key components of a lithium iron phosphate (LiFePO4) golf cart battery is essential for maximizing its performance and longevity. By recognizing how each part functions within the system, users can make informed decisions about maintenance and usage that enhance their overall experience.

FAQ Section

- What is a lithium iron phosphate golf cart battery?

It is a rechargeable battery designed specifically for electric golf carts using lithium iron phosphate as its cathode material. - How long do LiFePO4 golf cart batteries last?

They typically last between 10 to 15 years or more with proper maintenance. - What advantages do LiFePO4 batteries have over lead-acid batteries?

They offer longer lifespans, faster charging times, lower self-discharge rates, and improved safety features.