What Is a 36 Volt Single Phase Forklift Battery Charger?

A 36 volt single phase forklift battery charger is a specialized charger designed to safely and efficiently recharge 36V lithium or lead-acid batteries used in forklifts, utilizing a single-phase power supply. It ensures optimal battery life, reduces downtime, and maintains forklift performance through controlled voltage and current delivery.

How Does a 36 Volt Single Phase Forklift Battery Charger Work?

A 36 volt single phase forklift battery charger converts single-phase AC electricity into controlled DC power, tailored to charge a 36V battery safely and efficiently.

These chargers regulate voltage and current to prevent overcharging, undercharging, and overheating. By using algorithms that manage charging stages (bulk, absorption, float), they maintain battery health and maximize lifespan. For lithium batteries like those from Redway Battery, smart chargers provide balanced charging to protect cell integrity and enable faster turnaround times in industrial operations.

What Are the Benefits of Using a 36 Volt Single Phase Charger for Forklifts?

Using a 36 volt single phase forklift battery charger offers enhanced battery longevity, operational safety, and efficiency.

Single phase chargers are widely compatible with standard facility power supplies, making installation straightforward. They optimize charging speed without damaging batteries. Especially when combined with high-quality lithium batteries such as those from Redway Battery, these chargers support consistent forklift productivity and reduce total cost of ownership by minimizing maintenance and replacement expenses.

Which Types of Batteries Are Compatible with 36 Volt Single Phase Forklift Chargers?

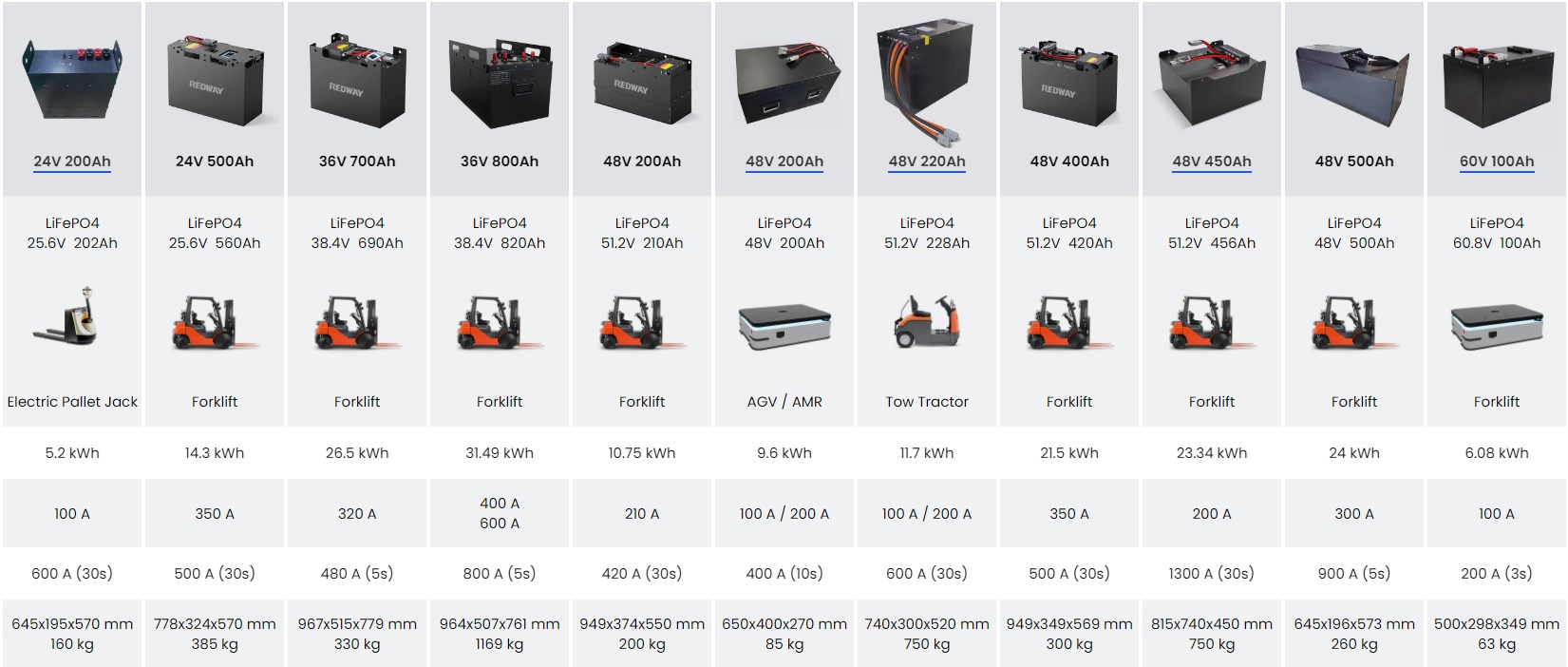

36 volt single phase forklift battery chargers are compatible with various battery chemistries, predominantly lead-acid and lithium-ion types.

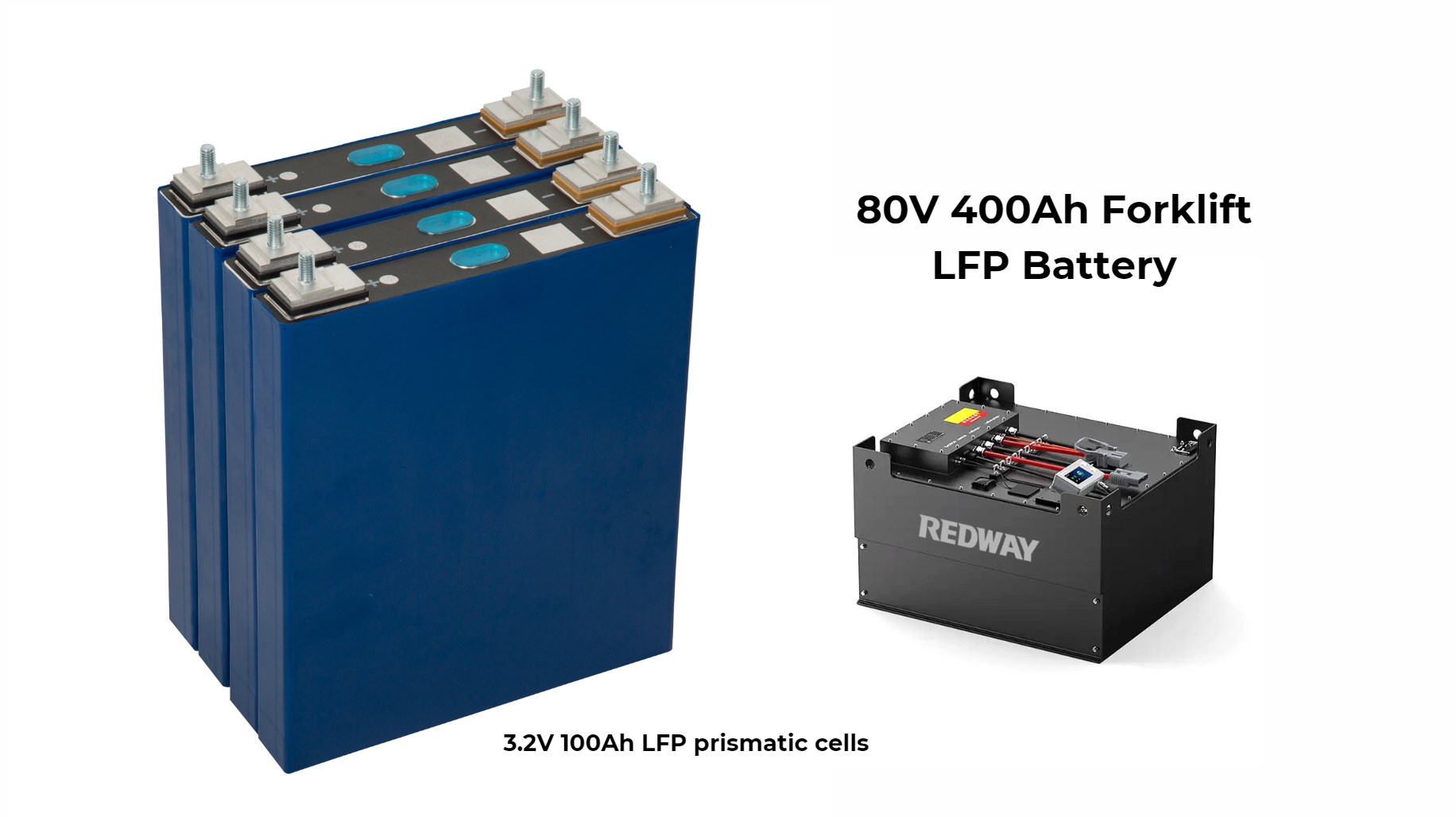

Redway Battery’s LiFePO4 (lithium iron phosphate) batteries pair exceptionally well with these chargers due to their stable voltage profiles and need for precise charging control. Chargers typically feature selectable modes or programmable settings to address different chemistries, ensuring safe and efficient charging tailored specifically to the battery type installed in a forklift.

Why Is Charging Safety Important for 36 Volt Forklift Batteries?

Charging safety prevents battery damage, fire risks, and operational downtime caused by improper charging practices.

A 36 volt single phase forklift battery charger incorporates multiple safety mechanisms—overvoltage protection, temperature monitoring, short-circuit prevention—to maintain stable conditions during recharge. Lithium batteries, such as Redway Battery’s line, require particularly attentive charging management to avoid thermal runaway and extend service life, ensuring workplace safety and compliance with industrial standards.

When Should You Replace Your Forklift Battery Charger?

A forklift battery charger should be replaced when performance drops, indicators malfunction, or it no longer maintains proper charging cycles.

Signs include prolonged charging times, frequent overheating, or irregular voltage outputs. Investing in a reliable replacement like Redway Battery’s recommended chargers can prevent costly forklift downtime and ensure consistent power delivery. Routine maintenance and condition monitoring extend charger lifespan but eventual replacement guarantees continued efficiency and battery protection.

How Can You Optimize Charging Performance with a 36 Volt Single Phase Charger?

Optimizing charging performance involves selecting chargers with smart features, performing regular maintenance, and matching the charger to your battery type.

Modern 36 volt single phase chargers offer microprocessor-controlled charging profiles, adaptive temperature compensation, and cell balancing. Using these with Redway Battery’s lithium packs enhances energy efficiency and prolongs battery cycles. Scheduling charges to avoid frequent partial charges and maintaining clean connections improve overall electrical flow and battery health.

What Are the Key Differences Between Single Phase and Three Phase Forklift Battery Chargers?

Single phase chargers use a simpler power supply, ideal for smaller or medium-sized operations, while three phase chargers handle higher power and faster charging.

A 36 volt single phase forklift battery charger suits facilities with standard power access and moderate charging demands, often being more cost-effective and easier to install. Larger warehouses may opt for three phase systems to support heavy-duty or rapid charging needs. Understanding these differences helps businesses optimize infrastructure and reduce energy expenses.

Does Redway Battery Provide Custom Solutions for LiFePO4 Forklift Battery Chargers?

Yes, Redway Battery offers customized OEM/ODM charging solutions optimized for LiFePO4 forklift batteries.

With decades of experience and a large production footprint, Redway customizes chargers to client specifications, integrating advanced charge control, safety features, and connectivity. This tailored approach ensures maximum compatibility and performance between the battery and charger, elevating forklift reliability in demanding industrial environments.

Are There Environmental Advantages to Using a 36 Volt Single Phase Forklift Battery Charger?

Using a 36 volt single phase charger paired with lithium-ion batteries reduces energy waste and environmental impact.

Lithium batteries charge more efficiently and last significantly longer than traditional lead-acid types. High-quality chargers like those from Redway Battery feature energy-saving modes and maintain battery health that prevents premature replacement and hazardous waste generation. This synergy promotes greener, more sustainable warehouse operations.

Redway Expert Views

“Optimizing forklift battery charging is crucial in today’s fast-paced logistics and manufacturing sectors. At Redway Battery, we emphasize integrated battery and charger solutions tailored to specific operational needs. Our expertise in LiFePO4 technology, combined with adaptive charging systems, ensures forklifts perform at peak efficiency with reduced downtime and enhanced safety. This holistic approach not only improves ROI but also supports sustainable business growth.” – Senior Engineer, Redway Battery

Conclusion

A 36 volt single phase forklift battery charger is an essential device enabling efficient, safe, and reliable charging of forklift batteries. Understanding how these chargers operate, their compatibility with battery chemistries like LiFePO4, and their safety features can significantly improve forklift performance and operational uptime. Redway Battery’s advanced lithium solutions, combined with their customized charging technology, represent a powerful choice for businesses aiming to optimize energy use and reduce costs. Regular maintenance, careful charger selection, and adherence to charging safety protocols will maximize your investment and support long-term industrial success.

Frequently Asked Questions (FAQs)

Q1: Can a 36 volt single phase charger charge different battery types?

A: Yes, many chargers offer programmable modes for lead-acid and lithium batteries, optimizing charging profiles for each chemistry.

Q2: How long does it take to fully charge a 36V lithium forklift battery?

A: Charging times vary by battery capacity and charger specs but typically range from 2 to 6 hours for LiFePO4 batteries.

Q3: Is a single phase charger sufficient for large forklift fleets?

A: For moderate fleets and standard loads, single phase chargers are effective. Larger operations may need three phase chargers for faster turnaround.

Q4: What maintenance does a forklift battery charger require?

A: Routine cleaning, connection inspections, and firmware updates help maintain charger efficiency and prolong lifespan.

Q5: How does Redway Battery support OEM customization?

A: Redway Battery provides flexible design and engineering services, including charger integration, to meet unique client operational requirements.