How Do You Safely Charge a Forklift with a Car Battery Charger?

Charging a forklift battery with a car battery charger is possible but requires precise steps to ensure safety and battery longevity. Use a suitable charger with appropriate voltage and current settings, monitor charging closely, and avoid overcharging to prevent damage.

What Are the Basic Differences Between Forklift and Car Batteries?

Forklift batteries are typically large, deep-cycle lead-acid or lithium-ion batteries designed for long-duration power supply. Car batteries are smaller, starting batteries providing brief, high current bursts. Forklift batteries operate at higher voltages and capacities, requiring chargers capable of handling their unique charging profiles.

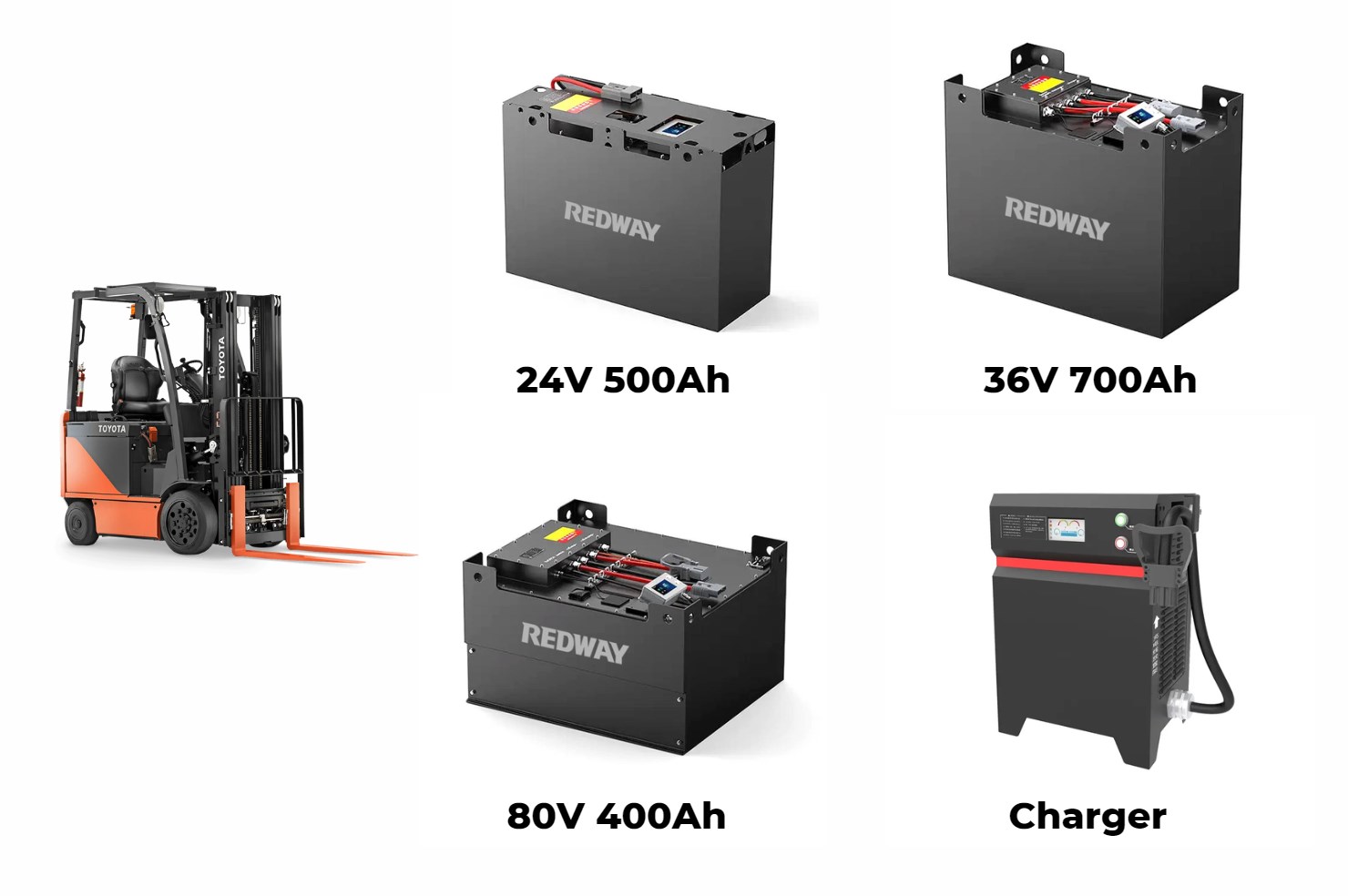

Forklift batteries generally consist of multiple cells providing 24V, 36V, 48V, or higher configurations, with ampere-hour (Ah) ratings far exceeding car batteries. They are built for deep discharge and recharge cycles. Car batteries, in contrast, deliver 12V with lower capacity meant to start an engine quickly. Hence, their charging needs differ significantly — forklift batteries benefit from slow, regulated charging that balances cell voltages, while car chargers may not have the correct settings to safely charge a forklift battery without modifications or precautions.

How Can You Use a Car Battery Charger to Charge a Forklift Battery?

You can charge some forklift batteries using a car battery charger if the charger matches the forklift battery voltage and current requirements. Adjust the charger to a lower amperage to avoid overcharging and monitor voltage closely during the process.

To charge a forklift battery with a car charger:

-

Confirm the forklift battery voltage (e.g., 24V) and check if the car charger can output this voltage or if multiple charges are needed in sequence.

-

Use a car charger with adjustable amperage settings, ideally using the lowest current setting.

-

Connect the charger’s positive lead to the battery’s positive terminal and the negative to the negative terminal.

-

Constantly monitor the battery’s voltage and temperature during charging to avoid overheating.

-

Stop charging once the battery voltage reaches the manufacturer’s recommended full charge voltage.

This process requires a diligent, manual approach and is not ideal for frequent use. Investing in a charger designed for forklift batteries, such as those from Redway Battery, is typically a safer and more efficient solution.

Why Is It Risky to Use a Car Battery Charger for Forklift Batteries?

Using a car battery charger on a forklift battery risks overcharging, undercharging, or damaging cells because the charger may not support the forklift’s higher voltage or charging profile. Overcharging can cause overheating, water loss, and reduced battery lifespan or dangerous failures.

Car chargers often lack the necessary charging stages designed for deep-cycle forklift batteries, such as bulk, absorption, and float phases. They may deliver excessive amperage too quickly or miss balancing the individual battery cells, leading to uneven wear. Furthermore, the difference in chemistry and battery size increases the likelihood of faulty readings and charger malfunction. For safety, specialized chargers calibrated for forklift batteries, like Redway Battery’s LiFePO4 charger options, use built-in management systems to protect battery health and extend service life.

When Should You Avoid Charging a Forklift Battery with a Car Charger?

Avoid charging if the forklift battery voltage exceeds what the car charger can safely handle, if the battery shows damage or leakage, or if you cannot monitor the charging parameters continuously. Also, avoid if frequent charging is required, as improper chargers will shorten battery life.

If the forklift battery uses advanced lithium batteries instead of standard lead-acid, car chargers are generally incompatible without special adapters or Battery Management System (BMS) integration. Environmental conditions—such as extreme temperatures or inadequate ventilation—also make improvised charging risky. Using dedicated chargers ensures compliance with manufacturer specifications and optimal battery care, which companies like Redway Battery emphasize in their safety recommendations.

Which Safety Steps Should Be Taken When Using a Car Battery Charger for Forklift Batteries?

Always wear protective gear, ensure proper ventilation, check charger and battery specifications for compatibility, connect terminals correctly, avoid sparks near the battery, and regularly inspect battery temperature and voltage during charging.

Key safety measures include:

-

Wearing insulated gloves and eye protection.

-

Charging in a well-ventilated area to prevent hydrogen gas buildup.

-

Confirming charger voltage and current settings match the forklift battery.

-

Double-checking connections to prevent polarity reversals.

-

Using a voltmeter and thermometer to monitor battery status.

-

Never leaving the battery unattended during charging, especially with an off-label charger.

These precautions reduce risks of acid spills, explosions, and permanent battery damage. For industrial applications, Redway Battery recommends using chargers designed specifically for forklift lithium batteries to ensure comprehensive safety through integrated monitoring systems.

How Does the Chemistry of Lithium Forklift Batteries Affect Charging Methods?

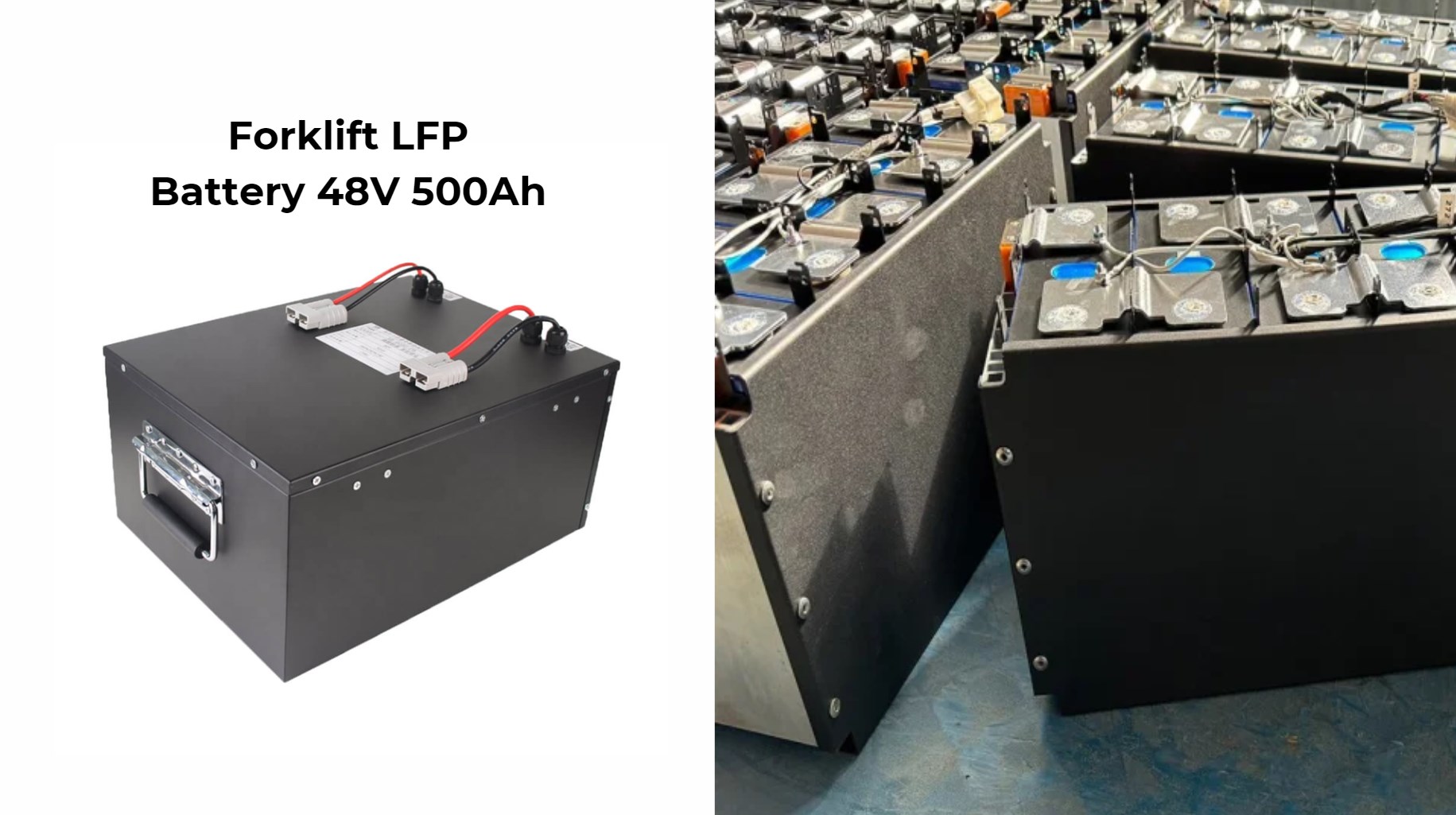

Lithium forklift batteries, such as LiFePO4, require precise voltage and current control with Battery Management Systems (BMS) to manage cell balancing, temperature, and overcharge protection. Car battery chargers designed for lead-acid batteries do not offer these features, which can risk lithium battery damage or safety hazards.

Lithium batteries charge differently than lead-acid types, using constant current-constant voltage (CC-CV) charging with strict cutoffs. The BMS protects against thermal runaway and overcharging. Using an unsuitable charger can cause cell imbalance, reduced capacity, or permanent failure. Redway Battery’s lithium forklift batteries come integrated with tailored BMS and compatible charger recommendations to maximize performance and safety.

What Are the Advantages of Using a Dedicated Forklift Battery Charger Over a Car Battery Charger?

Dedicated forklift chargers offer optimized charging profiles, adjustable voltage and current settings, built-in safety features, and faster, more efficient recharge cycles designed for large-capacity batteries, preserving battery health and extending lifespan.

Specialized chargers are designed to support multi-stage charging necessary for deep-cycle use, including equalization charging that balances cell voltage and prevents sulfation in lead-acid batteries. They often come with temperature sensors, digital displays, and automatic cutoff functions to prevent overcharging. While a car battery charger might work in emergencies or infrequent cases, using a high-quality forklift charger such as those provided by Redway Battery guarantees reliable, safe, and efficient charging tailored to your forklift’s battery chemistry.

Who Should Consider Upgrading to Lithium Forklift Batteries and Chargers?

Businesses relying heavily on forklifts and seeking longer battery life, faster charging, lighter weight, and reduced maintenance should consider lithium batteries and compatible chargers from experts like Redway Battery.

Unlike traditional lead-acid batteries requiring frequent watering and equalization, lithium batteries offer consistent performance, deeper discharge cycles, and more efficient energy use. Companies with environmental goals or high operational intensity find lithium solutions reduce total cost of ownership and downtime. Pairing lithium batteries with reliable chargers engineered by Redway Battery ensures safety, peak performance, and reduced operational complexity.

Table 1: Comparison of Car Battery vs. Forklift Battery Charging Parameters

| Parameter | Car Battery Charger | Forklift Battery Charger |

|---|---|---|

| Typical Voltage Output | 12V | 24V, 36V, 48V, or higher |

| Charging Current | 2–10A | 10–80A or higher (adjustable) |

| Charging Profile | Simple bulk/float cycles | Multi-stage with cell balancing |

| Safety Features | Basic overcharge protection | Advanced BMS integration |

| Suitable Battery Types | Lead-acid, 12V | Lead-acid deep cycle, LiFePO4 |

| Charging Time | 4–6 hours | 4–8 hours with fast charging |

Table 2: Key Safety Checklist for Charging Forklift Batteries with a Car Charger

| Safety Step | Description | Importance |

|---|---|---|

| Verify Voltage and Current | Match charger specs to battery | Prevents battery damage |

| Wear Protective Gear | Gloves, goggles | Protects against acid splashes |

| Ensure Ventilation | Prevent hydrogen gas buildup | Avoids explosion risk |

| Monitor Temperature Continuously | Use thermometer or infrared | Detects overheating early |

| Use Correct Connection Polarity | Positive to positive, negative to negative | Prevents sparks and short circuits |

| Do Not Leave Charging Unattended | Check battery regularly | Ensures prompt action if issues |

Redway Expert Views

“Forklift battery technology is evolving rapidly, particularly with the adoption of lithium-ion chemistries. At Redway Battery, we emphasize precise charging protocols and advanced Battery Management Systems to maximize battery life while ensuring safety. Our goal is to empower operators with high-performance, customizable solutions integrated with smart chargers, lowering operational costs and enhancing sustainability in material handling environments.” – Dr. Li Zhang, Chief Engineer, Redway Battery

Conclusion

Charging a forklift with a car battery charger is possible with careful voltage matching, reduced current, and vigilant monitoring, but it poses significant risks and limitations. Dedicated forklift chargers are safer, more efficient, and ensure optimal battery health—especially for lithium models. Companies should consider investing in purpose-built chargers like those from Redway Battery for long-term reliability and safety. Knowing your battery type, charger specifications, and safety practices can protect your investment and prevent operational disruptions.

Frequently Asked Questions (FAQs)

Q1: Can I charge any forklift battery with a car battery charger?

Only if the charger’s voltage output matches the forklift battery and you can control the current carefully. Otherwise, it’s unsafe and not recommended.

Q2: How long does it take to charge a forklift battery using a car charger?

It may take much longer than a dedicated charger because car chargers deliver lower current and lack optimized charging stages.

Q3: What happens if I overcharge a forklift battery?

Overcharging can cause overheating, battery swelling, electrolyte loss, and significantly shorten battery lifespan or cause safety hazards.

Q4: Are lithium forklift batteries compatible with car chargers?

Generally no, because lithium batteries require controlled CC-CV charging with BMS integration, which typical car chargers do not provide.

Q5: Where can I find reliable forklift battery chargers?

Redway Battery offers advanced chargers specifically designed for forklift lithium and lead-acid batteries with built-in safety and performance features.