How Do LiFePO4 Batteries Affect Forklift Performance?

LiFePO4 batteries significantly enhance forklift performance by offering longer operational uptime through fast and flexible charging, consistent high power delivery, improved energy efficiency, reduced maintenance, and enhanced safety due to superior thermal stability, making them a cost-effective and reliable solution for demanding industrial environments.

How Do LiFePO4 Batteries Increase Forklift Uptime and Productivity?

LiFePO4 batteries enable rapid charging, including opportunity charging during breaks, minimizing downtime and allowing continuous or multi-shift operations, thereby increasing forklift uptime and productivity.

How Does Faster Charging Improve Forklift Efficiency?

Faster recharge times reduce waiting periods, enabling forklifts to return quickly to work, supporting operational flow and maximizing equipment utilization.

What Are the Lifespan and Maintenance Benefits of LiFePO4 Batteries?

With cycle life often exceeding 3,500 cycles, these batteries outlast lead-acid significantly and require no watering or acid handling, eliminating routine maintenance and labor costs.

How Do LiFePO4 Batteries Maintain Consistent Power Output?

They provide stable voltage throughout discharge, preventing performance drops and ensuring forklifts operate at full power throughout shifts.

What Safety Advantages Do LiFePO4 Batteries Offer Compared to Lead-Acid?

LiFePO4 chemistry is chemically stable, resistant to thermal runaway, and free from acid leaks or hazardous gas emissions, making operations safer and cleaner.

How Do LiFePO4 Batteries Reduce Operational Costs?

Lower maintenance, fewer replacements, and reduced energy waste translate into significant savings over a battery’s lifecycle compared to traditional options.

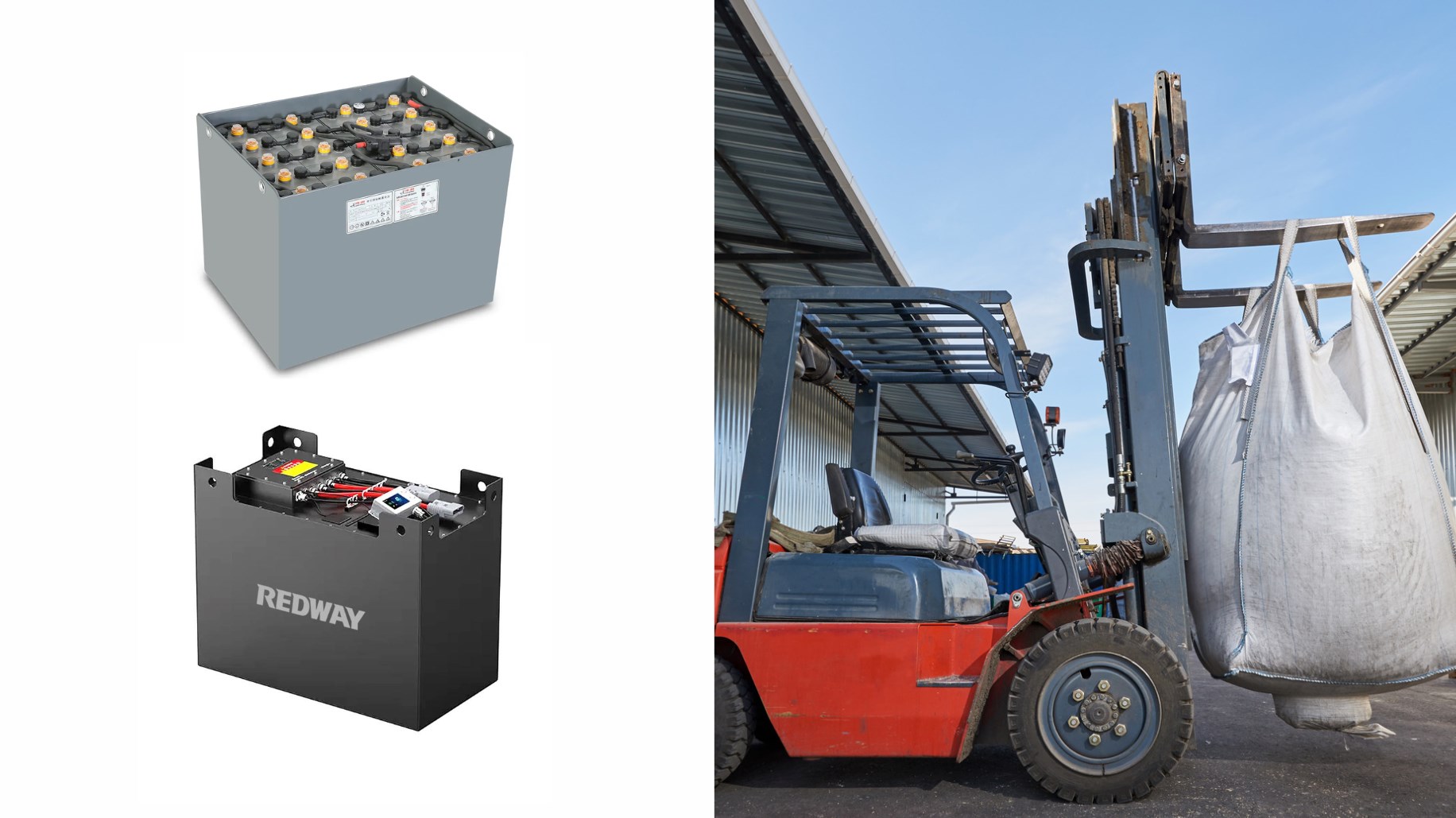

How Does Battery Weight Influence Forklift Performance?

Lighter LiFePO4 batteries improve vehicle maneuverability, acceleration, and energy efficiency, contributing to better operator control and reduced wear on equipment.

What Environmental Benefits Are Associated With LiFePO4 Forklift Batteries?

Longer lifespan reduces waste generation, and the absence of toxic materials like lead and acid lowers environmental hazards and facilitates recycling.

How Do LiFePO4 Batteries Perform in Extreme Temperature Conditions?

They maintain better performance than lead-acid in a wide temperature range but require proper thermal management for cold extremes to preserve efficiency.

How Does Opportunity Charging Optimize Battery Use?

Charging during short breaks helps maintain battery charge levels without damaging lifespan, supporting continuous workflow in busy warehouses.

How Can Operators Monitor and Maintain LiFePO4 Batteries Effectively?

Using battery management systems, regular voltage and temperature monitoring, and following manufacturer charging and storage guidelines ensure optimal lifespan and performance.

Chart: Key Performance Benefits of LiFePO4 Forklift Batteries

| Benefit | Explanation | Impact |

|---|---|---|

| Faster Charging | Allows rapid and opportunistic recharging | Increased uptime and utilization |

| Longer Lifespan | Exceeds 3,500 cycles versus fewer for lead-acid | Reduced replacement costs |

| Consistent Power | Maintains voltage under load | Steady forklift performance |

| Maintenance-Free | No watering or acid handling needed | Lower operational labor |

| Enhanced Safety | Stable chemistry reduces fire and leak risks | Safer working environment |

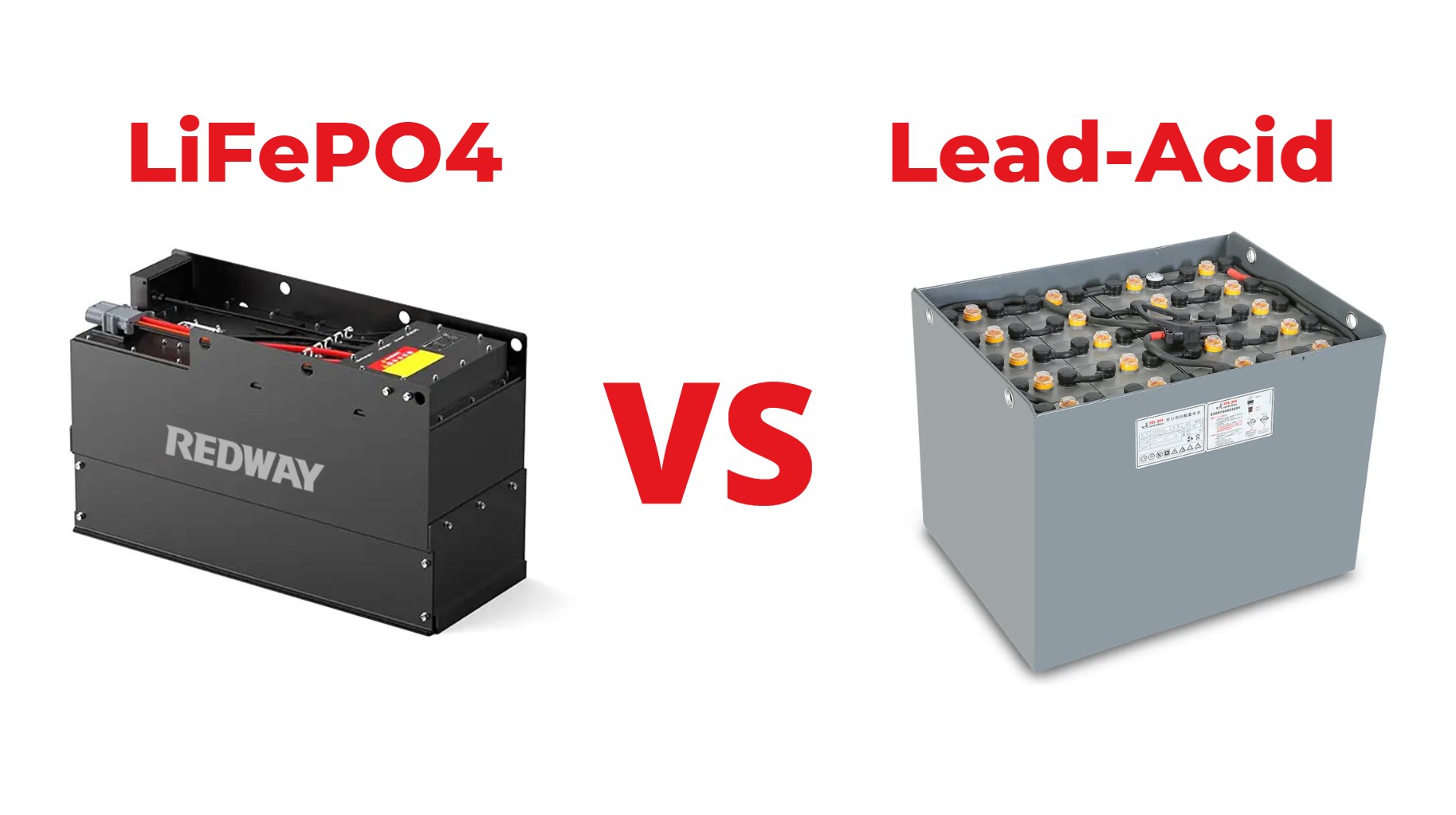

Chart: LiFePO4 vs Lead-Acid Cost and Performance Comparison

| Metric | LiFePO4 | Lead-Acid |

|---|---|---|

| Initial Cost | Higher | Lower |

| Maintenance | Minimal | Regular watering required |

| Cycle Life | 3,500+ cycles | 800-1,200 cycles |

| Weight | Lighter | Heavier |

| Charging Time | Fast | Slow |

Redway Battery Expert Views

“LiFePO4 batteries transform forklift operations by providing longer life, faster charging, and superior safety. Redway Battery’s cutting-edge lithium solutions help businesses increase productivity while reducing costs and environmental impact, making them vital to the future of intelligent material handling.” – Senior Engineer, Redway Battery

Conclusion

LiFePO4 batteries dramatically improve forklift performance through faster charging, longer life, consistent power, and reduced maintenance, offering substantial operational and cost benefits over traditional lead-acid batteries. Coupled with enhanced safety and environmental advantages, they represent the future of industrial battery technology.

FAQs

Q: How much longer do LiFePO4 batteries last compared to lead-acid?

A: Typically 3-4 times longer with over 3,500 cycles.

Q: Are LiFePO4 batteries maintenance-free?

A: Yes, they do not require watering or acid checks.

Q: Can LiFePO4 batteries be opportunity charged?

A: Yes, they support fast, flexible charging during breaks.

Q: How does battery weight affect forklift operation?

A: Lighter batteries improve handling, acceleration, and energy efficiency.