The main disadvantage of an AGM battery is its high initial cost. AGM batteries are generally more expensive upfront compared to traditional flooded lead-acid batteries. However, they offer advantages such as maintenance-free operation and better performance in certain applications.

-

High Initial Cost:

- AGM batteries typically have a higher upfront cost compared to traditional flooded lead-acid batteries. This can be a significant consideration, especially when multiple batteries are required for a specific application.

-

Maintenance-Free Operation:

- Despite the higher initial cost, AGM batteries offer maintenance-free operation, eliminating the need for regular water refilling and electrolyte checks. This can save time and effort in the long run.

-

Better Performance in Certain Applications:

- AGM batteries excel in applications that require deep cycling, high power output, and vibration resistance. They are commonly used in marine, RV, and off-grid solar power systems, where their superior performance justifies the higher cost.

Advantages of AGM batteries

The advantages of AGM batteries include maintenance-free operation, better vibration resistance, high power output, deep cycling capabilities, and longer lifespan. These features make AGM batteries suitable for various applications such as marine, RV, and off-grid solar power systems.

-

Maintenance-Free Operation:

- AGM batteries are sealed and do not require regular maintenance like adding water or checking electrolyte levels. This makes them convenient and hassle-free to use.

-

Vibration Resistance:

- AGM batteries are designed with a construction that provides better resistance to vibration. This makes them suitable for applications where the batteries may experience movement or vibration, such as in vehicles or boats.

-

High Power Output:

- AGM batteries can deliver high power output, making them suitable for applications that require a burst of energy or quick power delivery. This makes them ideal for starting engines in vehicles or powering electrical equipment.

-

Deep Cycling Capabilities:

- AGM batteries can withstand deep discharges and recharge cycles without losing performance. This makes them suitable for applications that require frequent and deep cycling, such as renewable energy systems or electric vehicles.

-

Longer Lifespan:

- AGM batteries generally have a longer lifespan compared to traditional flooded lead-acid batteries. This means they can provide reliable power for a longer period before needing replacement.

The main disadvantage of AGM batteries: high initial cost

The main disadvantage of AGM batteries is their high initial cost. AGM batteries are generally more expensive upfront compared to traditional flooded lead-acid batteries. However, they offer advantages such as maintenance-free operation and better performance in certain applications.

-

High Initial Cost:

- AGM batteries typically have a higher upfront cost compared to traditional flooded lead-acid batteries. This can be a significant consideration, especially when multiple batteries are required for a specific application.

-

Maintenance-Free Operation:

- Despite the higher initial cost, AGM batteries offer maintenance-free operation, eliminating the need for regular water refilling and electrolyte checks. This can save time and effort in the long run.

-

Better Performance in Certain Applications:

- AGM batteries excel in applications that require deep cycling, high power output, and vibration resistance. They are commonly used in marine, RV, and off-grid solar power systems, where their superior performance justifies the higher cost.

Factors that contribute to the higher cost

The higher cost of AGM batteries can be attributed to several factors. These include the construction and materials used in AGM batteries, the manufacturing process, and the incorporation of specific features and technologies. Despite the higher cost, AGM batteries offer advantages such as maintenance-free operation and better performance in certain applications.

-

Construction and Materials:

- AGM batteries are constructed differently from traditional flooded lead-acid batteries. They use an absorbent glass mat separator that holds the electrolyte in place, allowing for a more efficient and compact design. The materials used in AGM batteries, such as the glass mat and lead plates, are of higher quality, contributing to the overall cost.

-

Manufacturing Process:

- The manufacturing process for AGM batteries involves additional steps and specialized equipment compared to flooded lead-acid batteries. This includes the assembly of the AGM separator, precise filling of electrolyte, and sealing of the battery. These extra processes add to the production cost.

-

Specific Features and Technologies:

- AGM batteries often incorporate specific features and technologies to enhance their performance and durability. This can include advanced lead alloys, improved internal structures, and enhanced safety features. These additional features and technologies contribute to the higher cost of AGM batteries.

Comparison with other battery types

When comparing AGM batteries with other battery types like flooded lead-acid, lithium-ion, and gel batteries, it’s important to consider factors such as performance, cost, maintenance, and lifespan. AGM batteries offer advantages like maintenance-free operation, better vibration resistance, and deep cycling capabilities. However, each battery type has its own unique features and considerations. Evaluating these factors will help determine the most suitable battery type for specific applications.

-

Performance:

- AGM batteries offer maintenance-free operation, better vibration resistance, high power output, and deep cycling capabilities. Flooded lead-acid batteries are more affordable but require regular maintenance. Lithium-ion batteries offer high energy density and longer lifespan but come at a higher cost. Gel batteries provide good cycling performance but have lower power output.

-

Cost:

- AGM batteries have a higher initial cost compared to flooded lead-acid batteries but may have a similar or lower cost compared to lithium-ion batteries. Gel batteries can also be more expensive than AGM batteries. It’s important to consider the overall cost of ownership, including factors like maintenance and replacement.

-

Maintenance:

- AGM batteries are maintenance-free, requiring no watering or electrolyte checks. Flooded lead-acid batteries require regular maintenance, including adding water and checking electrolyte levels. Lithium-ion batteries and gel batteries are also maintenance-free.

Tips for minimizing the cost of an AGM battery

Minimizing the cost of an AGM battery can be achieved through strategies such as proper maintenance, considering alternative suppliers, comparing prices, and exploring warranty options. By implementing these tips, it’s possible to reduce the overall cost of owning an AGM battery.

-

Proper Maintenance:

- Regularly maintaining and caring for your AGM battery can extend its lifespan and optimize its performance. This includes following the manufacturer‘s guidelines for charging, avoiding overcharging or deep discharging, and keeping the battery clean and free from corrosion. By maximizing the lifespan of your AGM battery, you can minimize the need for frequent replacements.

-

Consider Alternative Suppliers:

- When purchasing an AGM battery, it’s worth exploring different suppliers and comparing prices. Different suppliers may offer varying prices and deals, so it’s important to research and find the most cost-effective option without compromising on quality. Consider reputable suppliers and read customer reviews to ensure reliability.

-

Compare Prices:

- Take the time to compare prices from different retailers or online platforms. Look for promotions, discounts, or bulk purchase options that can help reduce the cost per unit. It’s important to balance price with quality and consider the reputation of the seller.

-

Explore Warranty Options:

- AGM batteries often come with warranty options that can provide added value and cost savings. Familiarize yourself with the warranty terms and conditions, including coverage period and any limitations. Opting for a battery with a longer warranty period can provide peace of mind and potential cost savings in case of any issues.

Conclusion: Considering the overall benefits and drawbacks of AGM batteries

Considering the overall benefits and drawbacks of AGM batteries is crucial in making an informed decision. AGM batteries offer advantages like maintenance-free operation, better performance, and longer lifespan. However, they come with a higher initial cost and are sensitive to overcharging. Evaluating these factors will help determine the suitability of AGM batteries for specific applications.

-

Benefits of AGM Batteries:

- AGM batteries offer maintenance-free operation, eliminating the need for regular maintenance tasks like watering or electrolyte checks. They also provide better vibration resistance, making them suitable for applications where shocks and vibrations are common. AGM batteries have high power output, deep cycling capabilities, and a longer lifespan compared to traditional flooded lead-acid batteries.

-

Drawbacks of AGM Batteries:

- One of the main drawbacks of AGM batteries is their higher initial cost compared to flooded lead-acid batteries. AGM batteries are also sensitive to overcharging, which can lead to reduced performance and shortened lifespan. It’s important to use a compatible charger and follow the manufacturer’s guidelines to avoid overcharging.

-

Suitability for Specific Applications:

- Evaluating the benefits and drawbacks of AGM batteries is essential in determining their suitability for specific applications. AGM batteries are well-suited for applications that require reliable power, deep cycling capabilities, and minimal maintenance. They are commonly used in recreational vehicles, marine applications, backup power systems, and off-grid solar installations.

Final thoughts on whether the high initial cost is a major disadvantage or not

The high initial cost of AGM batteries may be seen as a major disadvantage, but it’s important to consider the long-term benefits. AGM batteries offer maintenance-free operation, longer lifespan, and improved performance, which can offset the initial investment and provide value over time. Evaluating these factors will help determine whether the high initial cost is a significant drawback or not.

-

Maintenance-Free Operation:

- AGM batteries offer maintenance-free operation, eliminating the need for regular maintenance tasks. This can result in cost savings over time, as there is no need to invest in additional maintenance equipment or spend time on maintenance activities.

-

Longer Lifespan:

- AGM batteries have a longer lifespan compared to traditional flooded lead-acid batteries. This means that they may not need to be replaced as frequently, reducing the overall cost of ownership in the long run.

-

Improved Performance:

- AGM batteries provide improved performance characteristics such as high power output and deep cycling capabilities. This can lead to increased productivity and reduced downtime, resulting in potential cost savings in various applications.

In conclusion, while the high initial cost of AGM batteries may be perceived as a major disadvantage, it’s important to consider the long-term benefits and cost-effectiveness. AGM batteries offer maintenance-free operation, longer lifespan, and improved performance, which can offset the initial investment and provide value over time. Evaluating these factors will help determine whether the high initial cost is a significant drawback or not.

FAQs

Is a Lithium Battery Considered a Flooded Battery?

A lithium battery and a flooded battery are distinct battery types. A lithium battery utilizes lithium-ion technology and does not require liquid electrolyte, while a flooded battery contains a liquid electrolyte that freely moves within the battery. The absence of liquid electrolyte in a lithium battery contributes to its lightweight and compact design, making it suitable for portable devices and electric vehicles. On the other hand, flooded batteries are commonly used in applications that require deep cycling and prolonged discharge periods. Each battery type has its own advantages and considerations, and the choice depends on the specific requirements of the application.

-

Lithium Battery: A lithium battery utilizes lithium-ion technology and does not require liquid electrolyte. This results in a lightweight and compact design, making it ideal for portable devices and electric vehicles. Lithium batteries offer high energy density and long cycle life, making them suitable for applications that require frequent charging and discharging.

-

Flooded Battery: A flooded battery, also known as a wet cell battery, contains a liquid electrolyte that freely moves within the battery. These batteries are commonly used in applications that require deep cycling and prolonged discharge periods. Flooded batteries are known for their durability and ability to handle high current loads. However, they require regular maintenance, including checking and refilling the electrolyte levels.

What Benefits Do Lithium-Ion Batteries Have Over AGM and Flooded?

Lithium-ion batteries have several advantages over AGM and flooded batteries. They offer higher energy density, longer lifespan, faster charging, lighter weight, lower self-discharge, and enhanced safety features. With a higher depth of discharge, lithium-ion batteries can utilize a larger percentage of their stored energy. They require minimal maintenance and are suitable for various applications such as solar energy storage, RVs, boats, and electric vehicles. Choose lithium-ion batteries for efficient and reliable power storage.

-

Higher Energy Density: Lithium-ion batteries have a higher energy density, meaning they can store more energy per unit of weight. This allows for smaller and lighter battery systems without compromising performance.

-

Longer Lifespan: Lithium-ion batteries have a longer lifespan compared to AGM and flooded batteries. They can withstand a greater number of charge-discharge cycles, resulting in a longer usable life.

-

Faster Charging: Lithium-ion batteries have faster charging capabilities, allowing for quicker replenishment of stored energy. This is especially beneficial in applications where fast charging is required.

-

Lighter Weight: Lithium-ion batteries are significantly lighter than AGM and flooded batteries. This weight reduction is advantageous in applications where weight savings are crucial, such as in RVs, boats, and portable devices.

-

Lower Self-Discharge: Lithium-ion batteries have a lower self-discharge rate, meaning they retain their charge for longer periods when not in use. This reduces the need for frequent recharging and ensures the battery remains ready for use.

-

Enhanced Safety Features: Lithium-ion batteries are designed with built-in safety features, such as battery management systems, to prevent overcharging, undercharging, and thermal runaway. This enhances the overall safety of the battery system.

Why Are Flooded Batteries Not Preferred Over AGM?

Flooded batteries are not preferred over AGM batteries due to several factors. Flooded batteries require regular maintenance, including checking and maintaining proper fluid levels and adding distilled water. They are more susceptible to damage from movement and extreme temperature conditions. AGM batteries, on the other hand, are maintenance-free and offer a longer lifespan. They have better resistance to vibrations and shocks, making them suitable for applications with infrequent or seasonal use. Choose AGM batteries for hassle-free and reliable power storage.

-

Regular Maintenance: Flooded batteries require regular maintenance, including checking and maintaining proper fluid levels and adding distilled water. This maintenance routine adds to the overall cost and effort of using flooded batteries. AGM batteries, on the other hand, are maintenance-free and do not require fluid level checks or topping up, providing convenience and ease of use.

-

Susceptibility to Damage: Flooded batteries are more susceptible to damage from movement and extreme temperature conditions. Any forceful movement can impact their ability to function at the highest level. Extreme temperatures, such as freezing in cold weather or evaporation in hot weather, can significantly affect the battery’s performance and lifespan. AGM batteries, with their sealed design and glass mat separators, are highly resistant to vibrations and shocks, ensuring reliable performance even in challenging conditions.

-

Longevity and Reliability: AGM batteries have a longer lifespan compared to flooded batteries, making them a more reliable choice. They offer better resistance to vibrations and shocks, ensuring durability in various applications. AGM batteries are ideal for applications with infrequent or seasonal use, as they can retain their charge for longer periods when not in use.

Can Flooded Batteries Replace AGM Batteries?

Replacing AGM batteries with flooded batteries may not be recommended due to the differences between the two battery types. AGM batteries are maintenance-free and offer advantages such as longer lifespan, higher resistance to vibrations, and better charge acceptance. On the other hand, flooded batteries require regular maintenance and have specific charging profiles that may not be compatible with AGM batteries. It is crucial to consider the specific requirements and characteristics of each battery type before making a replacement decision.

Do AGM Batteries Generally Last Longer Than Flooded Ones?

AGM batteries generally have a longer lifespan compared to flooded batteries. On average, AGM batteries can last anywhere from 4 to 8 years, depending on usage factors, charging practices, and environmental conditions. Flooded batteries, on the other hand, can provide an operating life of around 3 to 5 years with proper maintenance and careful consideration of charging methods. It is important to consider specific application requirements and maintenance practices when determining the lifespan of AGM and flooded batteries.

-

Lifespan of AGM Batteries: AGM batteries are known for their longer lifespan compared to flooded batteries. On average, AGM batteries can last anywhere from 4 to 8 years, depending on various factors such as usage patterns, charging practices, and environmental conditions. Proper care and maintenance can help maximize the lifespan of AGM batteries.

-

Lifespan of Flooded Batteries: While flooded batteries may not match the lifespan of AGM batteries, they can still provide a decent operating life with proper maintenance. On average, flooded batteries can last around 3 to 5 years. Regular maintenance, including checking and topping up electrolyte levels, and careful consideration of charging methods can help extend the lifespan of flooded batteries.

-

Factors Affecting Lifespan: The lifespan of both AGM and flooded batteries can be influenced by various factors. These include usage patterns, charging practices, environmental conditions (such as temperature and humidity), and maintenance routines. Following manufacturer guidelines and recommendations for proper care and maintenance is crucial in ensuring optimal performance and longevity.

How to Determine If a Battery Is AGM or Flooded?

To determine if a battery is AGM or flooded, you can check the label on the battery, which should clearly state the type. AGM batteries typically have a grey or black casing and are sealed tightly, while flooded batteries have removable caps for maintenance. AGM batteries are maintenance-free and do not require the addition of water, distinguishing them from flooded batteries. By looking for these indicators, you can easily identify the type of battery you have.

-

Checking the Label: One way to determine if a battery is AGM or flooded is by checking the label on the battery itself. The label should clearly state the type of battery, providing a straightforward identification method.

-

Physical Examination: Another way to identify the battery type is by examining its physical characteristics. AGM batteries typically have a grey or black casing and are tightly sealed, while flooded batteries have removable caps for maintenance. The design and color of the casing can provide clues about the battery type.

-

Maintenance Requirements: AGM batteries are maintenance-free and do not require the addition of water, distinguishing them from flooded batteries. AGM batteries are sealed, eliminating the need for regular fluid level checks. In contrast, flooded batteries require periodic maintenance, including checking and topping up electrolyte levels.

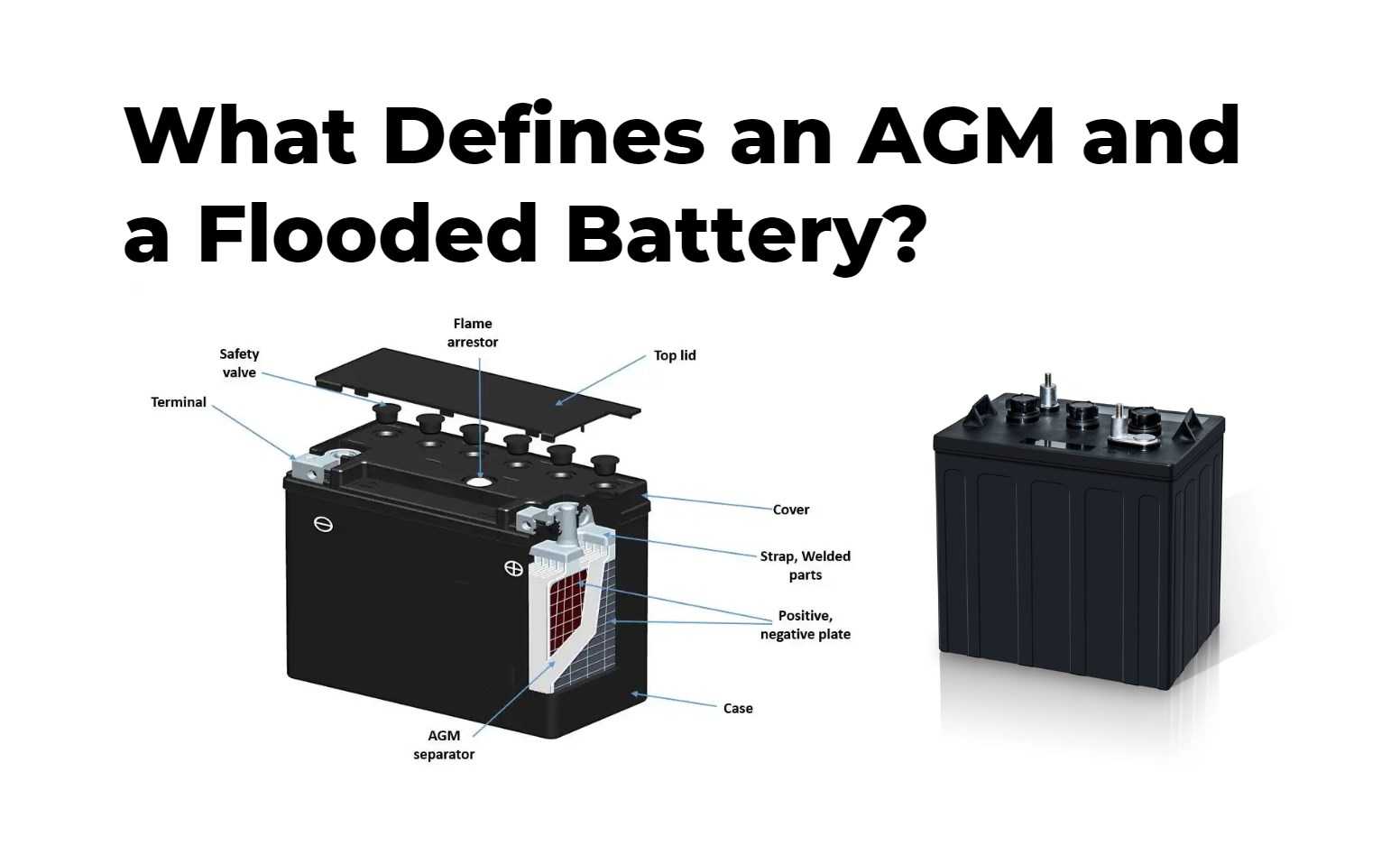

What Defines an AGM and a Flooded Battery?

AGM batteries are characterized by their sealed design with a fiberglass mat soaked in electrolyte, eliminating the need for maintenance associated with fluid levels. They are referred to as maintenance-free batteries and do not require the addition of water or electrolyte checks. Flooded batteries, on the other hand, have a traditional design with lead plates submerged in a liquid electrolyte solution. They require regular maintenance, including checking and topping up electrolyte levels. Understanding the defining characteristics of AGM and flooded batteries is crucial for selecting the appropriate battery type for specific applications.

-

AGM Batteries: AGM batteries feature a sealed design with a fiberglass mat soaked in electrolyte. This design eliminates the need for maintenance associated with fluid levels, making AGM batteries maintenance-free. They do not require the addition of water or electrolyte checks, providing convenience and ease of use.

-

Flooded Batteries: Flooded batteries have a traditional design with lead plates submerged in a liquid electrolyte solution. These batteries require regular maintenance, including checking and topping up electrolyte levels. The liquid electrolyte must be carefully measured and maintained to ensure proper battery performance.

-

Distinctive Features: The defining characteristics of AGM batteries include their sealed design, maintenance-free operation, and no requirement for water or electrolyte checks. On the other hand, flooded batteries are known for their traditional design, regular maintenance needs, and the ability to handle higher discharge rates.

Which Battery Type is Superior: AGM or Flooded?

The superiority of AGM or flooded batteries depends on specific application requirements. AGM batteries are maintenance-free and offer better resistance to vibrations and shocks. They have a lower self-discharge rate and perform well in extreme temperatures. On the other hand, flooded batteries are cost-effective and have a longer lifespan with regular maintenance. They can handle higher discharge rates and are commonly used in backup power applications. Choosing the superior battery type depends on factors such as maintenance preferences, power demands, and environmental conditions.

-

AGM Batteries: AGM batteries offer maintenance-free operation, resistance to vibrations and shocks, and a lower self-discharge rate. They perform well in extreme temperatures and provide a higher power output required for luxury and performance vehicles.

-

Flooded Batteries: Flooded batteries require regular maintenance but are cost-effective and have a longer lifespan when properly cared for. They can handle higher discharge rates and are commonly used in backup power applications, utility, and grid energy storage.

-

Application-Specific Considerations: The choice between AGM and flooded batteries depends on specific application requirements. AGM batteries are suitable for sealed and maintenance-free setups, while flooded batteries excel in applications where cost is a primary concern and regular maintenance can be performed. Factors such as power demands, environmental conditions, and budgetary constraints should be evaluated.