When evaluating energy storage solutions, maintenance costs are a crucial factor that impacts the overall total cost of ownership. LiFePO4 (Lithium Iron Phosphate) batteries and lead-acid batteries offer distinct advantages and challenges in terms of maintenance. This article provides a comprehensive comparison of their maintenance costs, highlighting key differences that affect long-term financial considerations.

LiFePO4 batteries incur lower maintenance costs compared to lead-acid batteries. Lead-acid requires regular electrolyte checks and watering, while LiFePO4’s sealed design eliminates these needs, resulting in reduced labor costs over time.

1. Maintenance Requirements

LiFePO4 Batteries: One of the primary advantages of LiFePO4 batteries is their virtually maintenance-free nature. These batteries do not require regular servicing tasks such as electrolyte level monitoring or terminal cleaning. The integrated Battery Management System (BMS) effectively manages the battery’s health, ensuring optimal performance without the need for user intervention. This lack of regular maintenance contributes to significant cost savings over the battery’s lifespan.

Lead-Acid Batteries: In contrast, lead-acid batteries demand regular maintenance to ensure their proper functioning. Routine tasks include checking and topping off electrolyte levels, cleaning terminals to prevent corrosion, and monitoring charging to avoid issues like stratification. These maintenance activities require time and effort, leading to higher operational costs associated with keeping the batteries in good condition.

2. Labor Costs

LiFePO4 Batteries: The minimal maintenance requirements of LiFePO4 batteries result in significantly lower labor costs. Since there are fewer routine tasks and no need for frequent inspections, users save on technician visits and maintenance labor. This reduction in labor costs contributes to overall financial savings and makes LiFePO4 batteries a more economical choice in the long run.

Lead-Acid Batteries: Regular maintenance tasks for lead-acid batteries lead to higher labor costs. Activities such as checking water levels, cleaning terminals, and ensuring proper charging can accumulate expenses over time. The frequency of these tasks can increase labor costs significantly, especially if performed consistently throughout the battery’s life.

3. Replacement Frequency

LiFePO4 Batteries: LiFePO4 batteries are known for their long lifespan, often exceeding 2,000 cycles, with some models reaching up to 7,100 cycles. This extended lifespan reduces the need for frequent replacements, which in turn lowers the associated costs of battery replacements and installation. The longevity of LiFePO4 batteries contributes to a more stable and predictable cost structure over their operational life.

Lead-Acid Batteries: Lead-acid batteries generally have a shorter lifespan, ranging from 300 to 1,000 cycles depending on the type and usage conditions. This shorter lifespan results in more frequent replacements, increasing both replacement costs and labor costs associated with battery installation. The need for more frequent replacements can significantly impact the total cost of ownership over time.

4. Total Cost of Ownership

When assessing the total cost of ownership, which encompasses initial purchase costs, maintenance expenses, and replacement costs, LiFePO4 batteries often emerge as the more cost-effective option despite their higher upfront price. The reduced need for maintenance, coupled with their longer lifespan, results in lower overall costs compared to lead-acid batteries. Lead-acid batteries, while cheaper initially, can incur higher ongoing expenses due to frequent maintenance and replacement needs.

Conclusion

In summary, LiFePO4 batteries offer significant advantages over lead-acid batteries in terms of maintenance costs. Their minimal maintenance requirements, extended lifespan, and reduced replacement frequency make them a more economical choice in the long term. While lead-acid batteries may have a lower initial cost, the higher maintenance and replacement expenses can accumulate, making LiFePO4 batteries a more cost-effective solution for reliable and continuous power.

FAQs

What Safety Measures Should Be Taken When Using LiFePO4 Forklift Batteries?

Do LiFePO4 Batteries Require Maintenance?

What is the Typical Cost of a LiFePO4 Forklift Battery?

Comparing Maintenance Costs: LiFePO4 Batteries vs. Lead-Acid Batteries

Exploring Real-World Applications of LiFePO4 Batteries in Forklifts

Industries Benefiting from LiFePO4 Forklift Batteries

What is LiFePO4 Technology?

The Evolving Market for Forklift Batteries

What Are the Latest Advancements in LiFePO4 Battery Technology?

How Does Fast Charging Impact Battery Life?

Types of Chargers for LiFePO4 Forklift Batteries

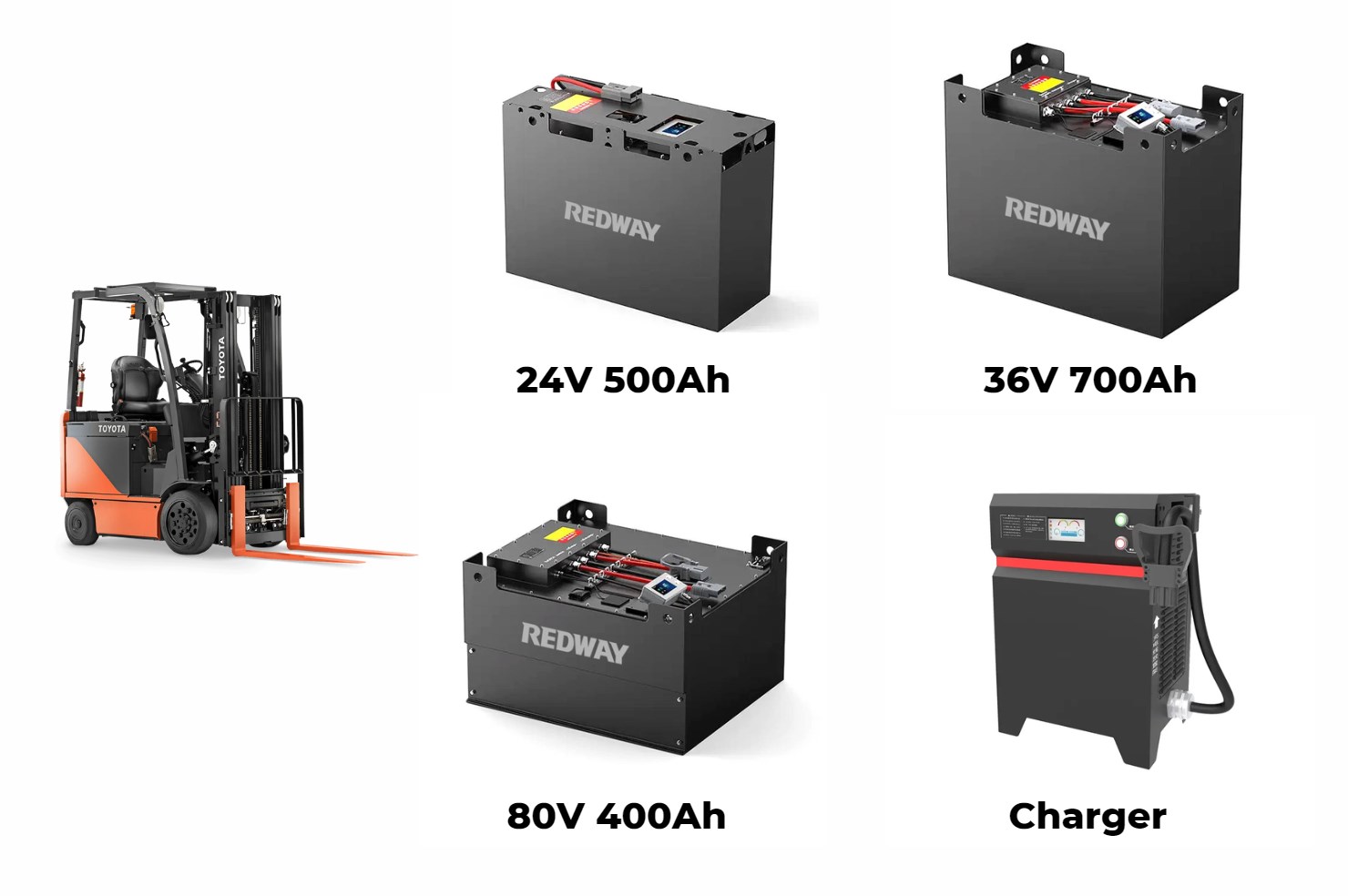

Common Voltage and Capacity Options for LiFePO4 Forklift Batteries

Comparing LiFePO4 and Lead-Acid Batteries: A Comprehensive Analysis