What Makes CjA Telecommunications’ Battery Systems in Silverton Essential?

CjA Telecommunications in Silverton, Pretoria, provides critical battery backup solutions for uninterrupted power in telecom infrastructure. Their systems use advanced lithium-ion and VRLA batteries, ensuring reliability during load-shedding. These installations support cellular networks, data centers, and emergency services, making them vital for maintaining connectivity and operational continuity in South Africa’s energy-challenged grid.

Why Are Battery Backup Systems Critical for Telecommunications?

Telecom networks require 24/7 power to maintain voice/data services. CjA’s battery systems prevent service disruptions during outages, ensuring compliance with regulatory uptime requirements. Their Silverton facility uses temperature-controlled enclosures and real-time monitoring to optimize performance.

How Do Different Battery Types Enhance Reliability?

CjA uses lithium-ion batteries for high energy density and VRLA (Valve-Regulated Lead-Acid) for cost efficiency. Lithium-ion offers 5,000+ cycles and 10-year lifespans, while VRLA provides 3-5 years of service. Hybrid configurations balance performance and budget needs, adapting to Pretoria’s frequent power fluctuations.

What Environmental Safeguards Are Implemented?

CjA’s Silverton site follows ISO 14001 standards, using recyclable battery components and solar-assisted charging. Spent batteries undergo certified recycling to recover lead/plastic. Thermal management systems prevent acid leaks, reducing soil contamination risks.

How Does Battery Maintenance Prolong System Lifespan?

Bi-monthly voltage checks, quarterly load testing, and annual capacity audits ensure peak performance. CjA’s IoT-enabled sensors track sulfation levels in lead-acid batteries and lithium-ion cell balancing, automatically alerting technicians to anomalies.

Can Businesses Customize Battery Configurations?

Yes. CjA offers modular designs scalable from 5kWh (small towers) to 500kWh (data centers). Clients choose between centralized vs. decentralized layouts, with optional generator integration. Custom BMS (Battery Management Systems) align with specific discharge depth requirements.

What ROI Can Companies Expect from These Systems?

Typical ROI periods range 18-36 months. Savings come from reduced diesel costs (40-60% lower) and penalty avoidance for SLA breaches. Case studies show R1.2 million/year savings for mid-sized ISPs using CjA’s lithium solutions.

Expert Views

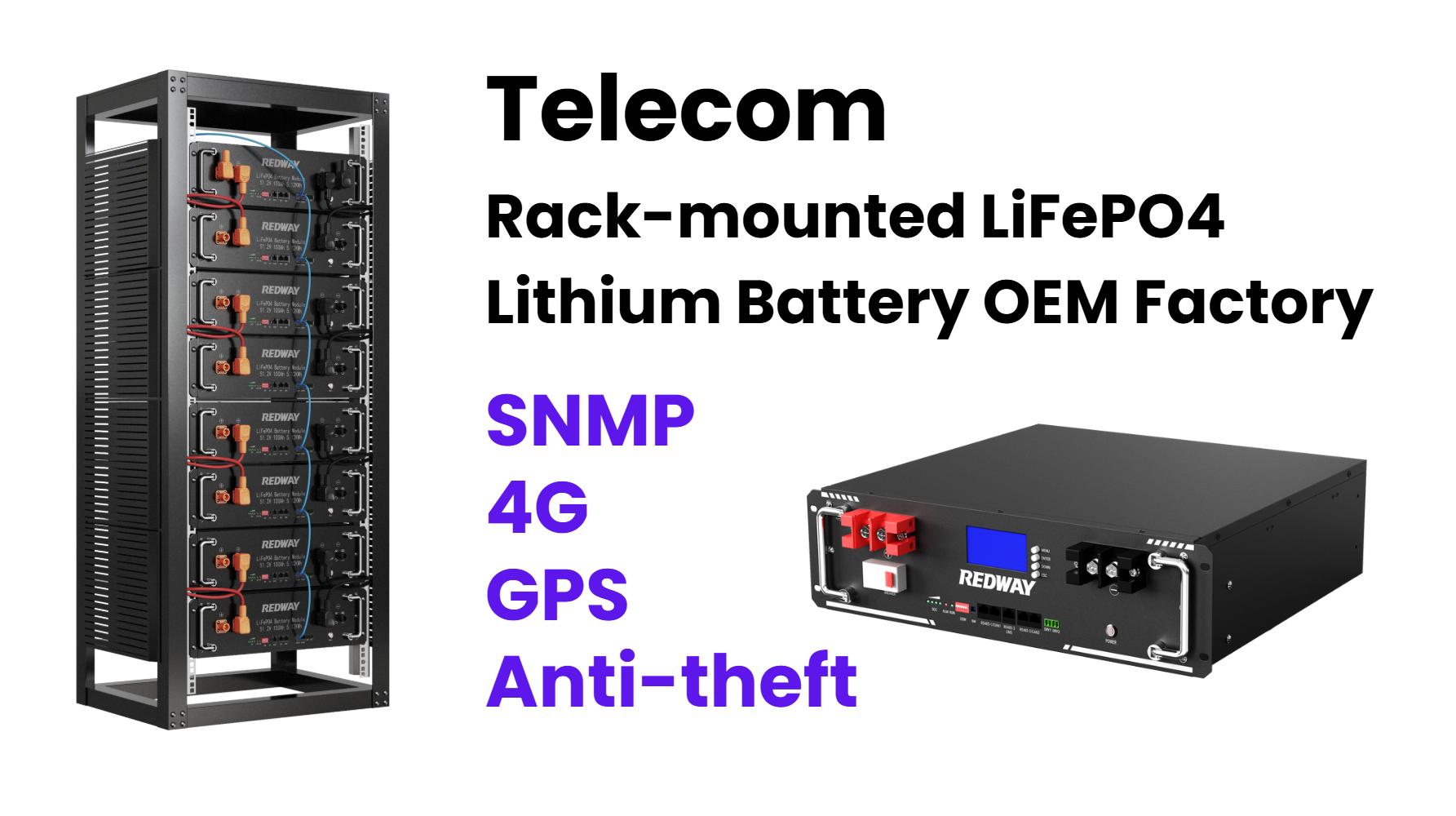

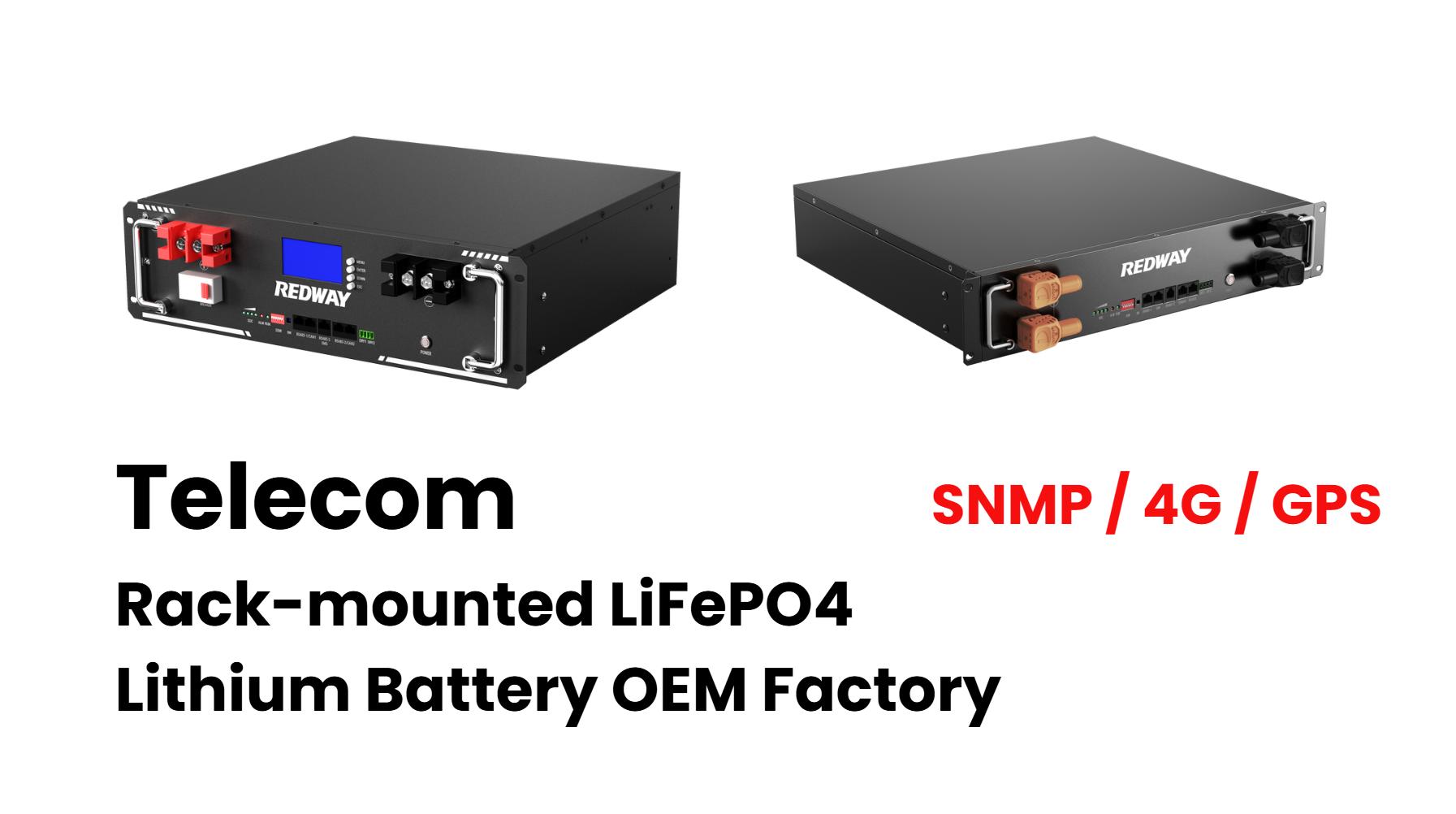

“CjA’s Silverton deployment addresses South Africa’s dual challenges of energy scarcity and digital expansion,” says a Redway Power Solutions engineer. “Their adaptive topology allows seamless upgrades to future tech like vanadium flow batteries. This forward-thinking approach minimizes stranded assets in telecom infrastructure.”

Conclusion

CjA Telecommunications’ Silverton battery systems exemplify mission-critical power resilience. Through cutting-edge chemistry, proactive maintenance, and environmental stewardship, they maintain South Africa’s digital lifelines amid escalating blackouts.

FAQs

How long do CjA’s batteries last during outages?

Most systems provide 8-72 hours of backup, depending on load. Critical sites use generator hybridization for indefinite runtime.

Are these batteries compatible with solar power?

Yes. CjA integrates PV panels with battery banks, reducing grid dependence by 30-70%. Smart inverters manage dual-input charging.

What certifications do CjA’s installations hold?

All systems meet SANS 50196, IEC 61427, and NEC 2020 standards. Third-party insurers like Lloyd’s certify their fire safety protocols.