What Are the Critical Components of a Data Center Battery Room?

A data center battery room houses backup power systems, primarily uninterruptible power supply (UPS) batteries, to ensure continuous operations during grid failures. These rooms require temperature control, safety protocols, and redundant configurations to maintain uptime, protect equipment, and mitigate risks like thermal runaway or fire.

How Do Data Center Battery Rooms Ensure Power Continuity?

Battery rooms use UPS systems paired with lithium-ion or VRLA batteries to bridge power gaps between grid failure and generator activation. Redundant battery strings, automated monitoring, and regular load testing ensure seamless failover. For example, hyperscale data centers often deploy N+1 redundancy to eliminate single points of failure.

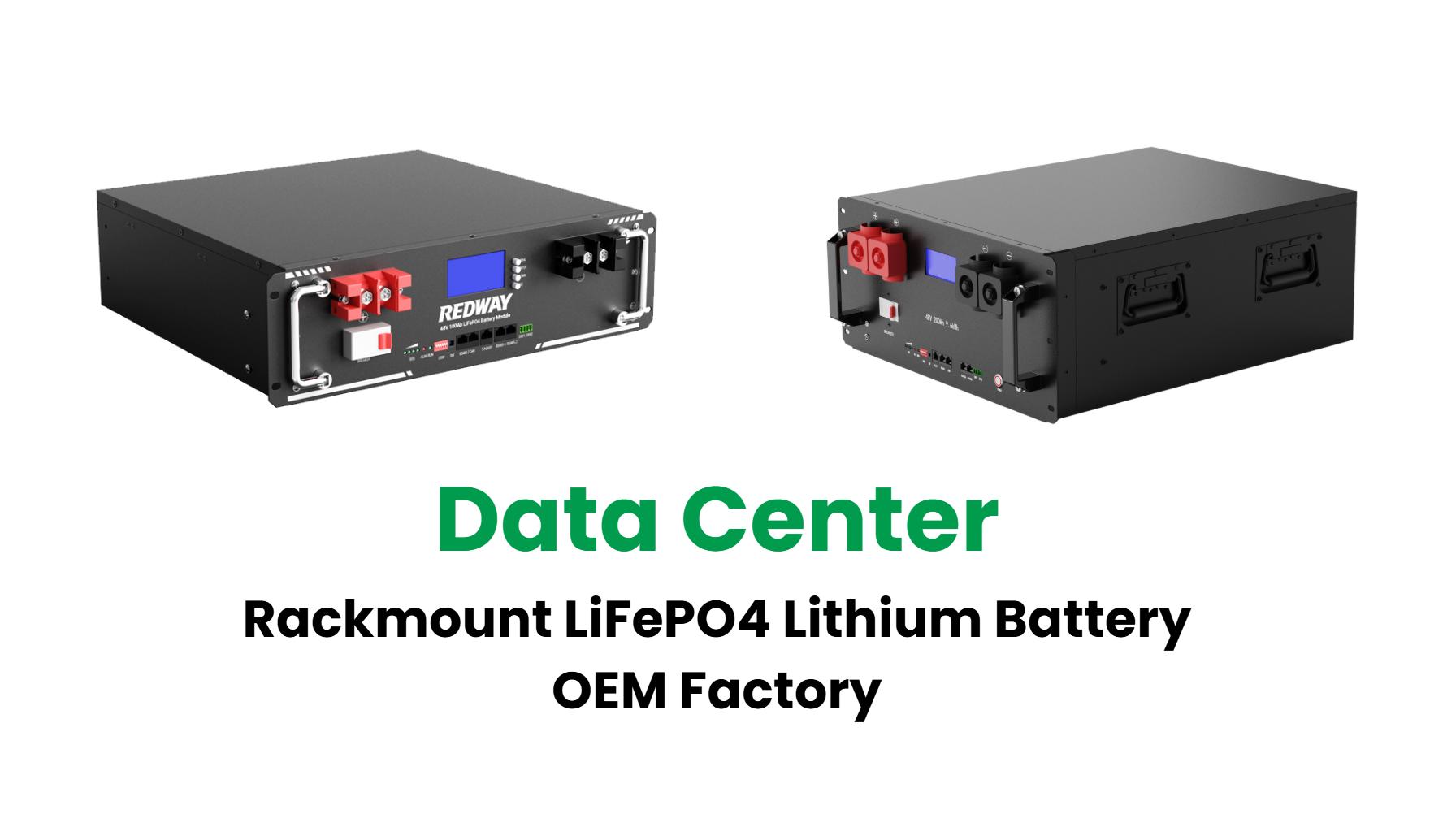

What Battery Technologies Are Used in Modern Data Centers?

Lithium-ion batteries dominate due to higher energy density, longer lifespan, and faster charging compared to traditional VRLA. Nickel-Zinc and flow batteries are emerging for niche applications. Tesla’s Megapack, for instance, is used in large-scale deployments for its modularity and scalability.

Why Are Thermal Management Systems Vital for Battery Rooms?

Batteries generate heat during charge/discharge cycles. Excess heat accelerates degradation and raises fire risks. Data centers use precision cooling, aisle containment, and liquid cooling systems to maintain 20–25°C. Google’s battery rooms employ AI-driven cooling to optimize energy use while preventing thermal runaway.

How Are Fire Risks Mitigated in Battery Storage Areas?

Fire suppression systems like clean agent gas (e.g., FM-200) and aqueous film-forming foam (AFFF) are standard. Battery cabinets with built-in venting, smoke detectors, and thermal sensors provide early warnings. The NFPA 855 standard mandates spacing and compartmentalization to limit fire spread.

What Role Does Battery Monitoring Software Play?

Real-time monitoring tracks voltage, temperature, and state of charge to predict failures. Platforms like Schneider Electric’s EcoStruxure use machine learning to analyze trends and schedule maintenance. AWS reported a 40% reduction in downtime after implementing predictive analytics for battery health.

How Does Battery Room Design Impact Energy Efficiency?

Layout optimization reduces energy loss. Short cable runs, modular racks, and high-efficiency converters minimize resistance. Facebook’s battery rooms use 48V DC architectures, cutting conversion losses by 30% compared to traditional 12V systems.

Expert Views

“Lithium-ion adoption is accelerating, but legacy VRLA systems remain relevant for cost-sensitive deployments. The key is balancing CAPEX with lifecycle costs—advanced monitoring can extend VRLA lifespan by 20%.”

— James Carter, Power Systems Engineer at Redway

Conclusion

Data center battery rooms are engineering marvels combining cutting-edge tech and rigorous safety protocols. As demand for uptime grows, innovations in lithium-ion efficiency, AI-driven monitoring, and modular design will redefine resilience standards.

FAQs

How Often Should Data Center Batteries Be Replaced?

VRLA batteries typically last 3–5 years, while lithium-ion lasts 10–15 years. Replacement cycles depend on usage patterns and monitoring data.

Can Data Centers Use Renewable Energy for Battery Charging?

Yes. Solar/wind can charge batteries, but grid integration requires advanced inverters and frequency regulation. Microsoft’s Dublin data center runs 100% on renewables, with batteries smoothing intermittent supply.

Are Solid-State Batteries Viable for Data Centers?

Solid-state batteries offer higher safety and energy density but remain cost-prohibitive. Pilot projects are underway, with commercial viability expected post-2030.