When considering the efficiency and effectiveness of your solar power system, a common question arises: Can I mix 100 watt and 200 watt solar panels? This question is crucial for optimizing your solar energy setup and ensuring you make the most of your investment. In this guide, we will delve into the complexities of combining different wattage solar panels and how to achieve the ultimate performance from your solar array.

Understanding Solar Panel Wattage

Before diving into the specifics of mixing solar panels, it is essential to understand the significance of solar panel wattage. Wattage represents the amount of power a solar panel can generate under optimal conditions. A 100-watt panel can produce 100 watts of power, while a 200-watt panel can generate twice that amount. Despite their different capacities, both types of panels convert sunlight into electricity, but their performance characteristics can impact the overall efficiency of your system.

Technical Considerations for Mixing Panels

When mixing solar panels of different wattages, several technical considerations come into play:

1. Voltage Compatibility

The most critical factor is the voltage compatibility of the panels. Solar panels should ideally have matching voltage outputs when connected in series. Connecting panels with different voltages can lead to inefficiencies and potential damage. To ensure compatibility, check the voltage rating of each panel and confirm that they match or are within a safe range.

2. Current Matching

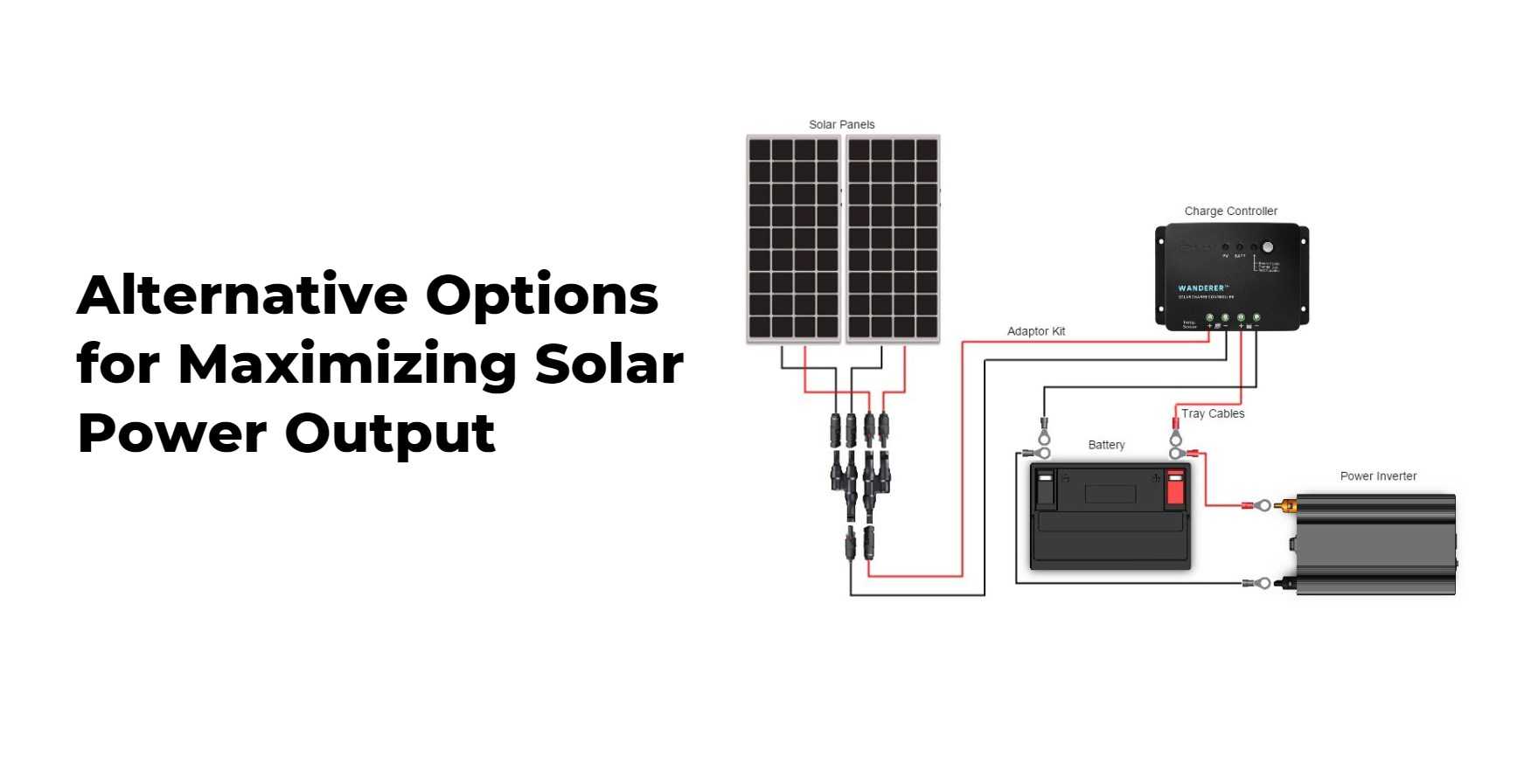

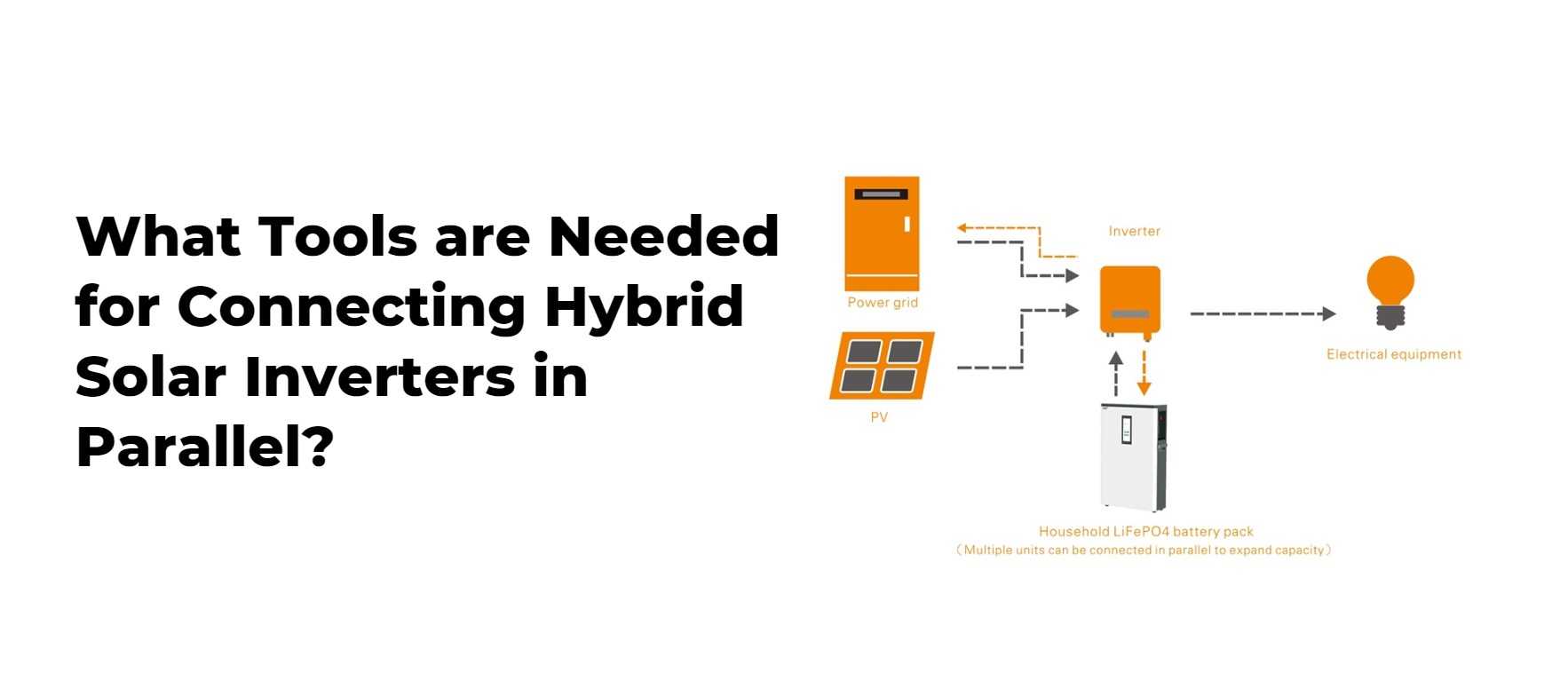

While voltage matching is crucial, current matching is also significant. Panels with different wattages will have different current outputs. When panels are connected in parallel, their currents add up, but their voltages remain the same. Ensure that the current rating of the panels aligns with your system’s requirements to avoid overloading your inverter or charge controller.

3. Wiring and Inverter Sizing

The wiring configuration and inverter sizing are vital considerations. When panels of different wattages are connected, it is essential to use appropriately sized wiring to handle the combined current. Additionally, the inverter should be capable of handling the total power output of the combined panels. A mismatch can lead to inefficiencies or potential system failure.

System Performance and Efficiency

Mixing panels of different wattages can impact the overall performance and efficiency of your solar power system. Here are some factors to consider:

1. Power Output Optimization

Combining 100 watt and 200 watt panels may result in a non-optimal power output if not correctly configured. To maximize performance, ensure that the panels are arranged in a way that allows for the most efficient energy conversion. This may involve using a maximum power point tracking (MPPT) charge controller to optimize energy harvest.

2. Shade and Orientation

The shade and orientation of the panels can affect their performance. Panels with different wattages should be placed to avoid shading each other and should be oriented for optimal sunlight exposure. Consistent shading or misalignment can lead to decreased efficiency and performance.

3. System Balance

Maintaining a balanced system is crucial for efficient energy production. Mixing different wattages can lead to imbalances in power production, which may impact the overall efficiency. Ensure that your system design accounts for these differences and optimizes the energy output.

Practical Tips for Mixing Solar Panels

To achieve the best results when mixing 100 watt and 200 watt solar panels, follow these practical tips:

1. Consult a Professional

Engage with a solar energy professional or electrical engineer to assess your system and provide guidance on the optimal configuration. Their expertise will help ensure that your system is designed for maximum efficiency and safety.

2. Use Compatible Components

Ensure that all system components, including the inverter, charge controller, and wiring, are compatible with the mixed wattage panels. This will help prevent any issues related to performance or safety.

3. Regular Maintenance and Monitoring

Implement a regular maintenance and monitoring routine to ensure that your solar system operates efficiently. This includes checking for any issues related to panel performance, wiring, and system components.

Advantages and Disadvantages of Mixing Panels

Advantages

- Flexibility: Allows you to integrate different panel types based on availability and budget.

- Cost-Effective: Potentially reduces the upfront cost of installing a solar power system.

Disadvantages

- Reduced Efficiency: Potential for decreased system efficiency due to mismatched panels.

- Complexity: Increased complexity in system design and maintenance.

Conclusion

In summary, mixing 100 watt and 200 watt solar panels is possible, but it requires careful consideration of several technical factors, including voltage and current compatibility, wiring, and inverter sizing. By understanding these factors and following best practices, you can optimize your solar power system for maximum efficiency and performance. For the ultimate results, consulting with a professional and ensuring that all system components are compatible will help you achieve a well-balanced and effective solar energy solution.

When considering the efficiency and effectiveness of your solar power system, a common question arises: Can I mix 100 watt and 200 watt solar panels? This question is crucial for optimizing your solar energy setup and ensuring you make the most of your investment. In this guide, we will delve into the complexities of combining different wattage solar panels and how to achieve the ultimate performance from your solar array.

Understanding Solar Panel Wattage

Before diving into the specifics of mixing solar panels, it is essential to understand the significance of solar panel wattage. Wattage represents the amount of power a solar panel can generate under optimal conditions. A 100-watt panel can produce 100 watts of power, while a 200-watt panel can generate twice that amount. Despite their different capacities, both types of panels convert sunlight into electricity, but their performance characteristics can impact the overall efficiency of your system.

Technical Considerations for Mixing Panels

When mixing solar panels of different wattages, several technical considerations come into play:

1. Voltage Compatibility

The most critical factor is the voltage compatibility of the panels. Solar panels should ideally have matching voltage outputs when connected in series. Connecting panels with different voltages can lead to inefficiencies and potential damage. To ensure compatibility, check the voltage rating of each panel and confirm that they match or are within a safe range.

2. Current Matching

While voltage matching is crucial, current matching is also significant. Panels with different wattages will have different current outputs. When panels are connected in parallel, their currents add up, but their voltages remain the same. Ensure that the current rating of the panels aligns with your system’s requirements to avoid overloading your inverter or charge controller.

3. Wiring and Inverter Sizing

The wiring configuration and inverter sizing are vital considerations. When panels of different wattages are connected, it is essential to use appropriately sized wiring to handle the combined current. Additionally, the inverter should be capable of handling the total power output of the combined panels. A mismatch can lead to inefficiencies or potential system failure.

System Performance and Efficiency

Mixing panels of different wattages can impact the overall performance and efficiency of your solar power system. Here are some factors to consider:

1. Power Output Optimization

Combining 100 watt and 200 watt panels may result in a non-optimal power output if not correctly configured. To maximize performance, ensure that the panels are arranged in a way that allows for the most efficient energy conversion. This may involve using a maximum power point tracking (MPPT) charge controller to optimize energy harvest.

2. Shade and Orientation

The shade and orientation of the panels can affect their performance. Panels with different wattages should be placed to avoid shading each other and should be oriented for optimal sunlight exposure. Consistent shading or misalignment can lead to decreased efficiency and performance.

3. System Balance

Maintaining a balanced system is crucial for efficient energy production. Mixing different wattages can lead to imbalances in power production, which may impact the overall efficiency. Ensure that your system design accounts for these differences and optimizes the energy output.

Practical Tips for Mixing Solar Panels

To achieve the best results when mixing 100 watt and 200 watt solar panels, follow these practical tips:

1. Consult a Professional

Engage with a solar energy professional or electrical engineer to assess your system and provide guidance on the optimal configuration. Their expertise will help ensure that your system is designed for maximum efficiency and safety.

2. Use Compatible Components

Ensure that all system components, including the inverter, charge controller, and wiring, are compatible with the mixed wattage panels. This will help prevent any issues related to performance or safety.

3. Regular Maintenance and Monitoring

Implement a regular maintenance and monitoring routine to ensure that your solar system operates efficiently. This includes checking for any issues related to panel performance, wiring, and system components.

Advantages and Disadvantages of Mixing Panels

Advantages

- Flexibility: Allows you to integrate different panel types based on availability and budget.

- Cost-Effective: Potentially reduces the upfront cost of installing a solar power system.

Disadvantages

- Reduced Efficiency: Potential for decreased system efficiency due to mismatched panels.

- Complexity: Increased complexity in system design and maintenance.

Conclusion

In summary, mixing 100 watt and 200 watt solar panels is possible, but it requires careful consideration of several technical factors, including voltage and current compatibility, wiring, and inverter sizing. By understanding these factors and following best practices, you can optimize your solar power system for maximum efficiency and performance. For the ultimate results, consulting with a professional and ensuring that all system components are compatible will help you achieve a well-balanced and effective solar energy solution.