Why 18650 Battery Would Explode?

The safety and efficiency of 18650 batteries are paramount for both consumers and manufacturers. These batteries, integral to a wide range of electronic devices, possess remarkable energy density but come with inherent risks if mishandled. Our objective is to provide an in-depth guide on understanding and preventing 18650 battery explosions, ensuring safe usage and extending battery life.

Understanding Thermal Runaway

What is Thermal Runaway?

Thermal runaway is a critical condition in lithium-ion batteries, including 18650 cells, where an increase in temperature leads to a self-sustaining reaction. This phenomenon can result in severe consequences such as explosions or fires.

Causes of Thermal Runaway

Thermal runaway is induced by several factors:

- Overcharging: Charging beyond the battery’s maximum voltage can generate excess heat.

- Overdischarging: Depleting the battery below its safe voltage threshold destabilizes its chemistry.

- Short-circuiting: Direct contact between positive and negative terminals results in rapid heat generation.

- Physical Damage: Punctures or dents can compromise internal structures, leading to runaway.

- High Temperatures: Prolonged exposure to heat accelerates material breakdown.

- Poor Quality Batteries: Counterfeit or substandard batteries lack necessary safety features.

Prevention Strategies

Ensuring High-Quality Batteries

- Source from Reputable Manufacturers: Always purchase 18650 batteries from trusted suppliers to guarantee adherence to safety standards.

- Avoid Counterfeits: Be wary of significantly cheaper batteries, as they might be counterfeit and pose safety risks.

Proper Charging Practices

- Use Reliable Chargers: Utilize chargers equipped with overcharge protection to prevent exceeding safe voltage limits.

- Monitor Charging: Regularly check the battery during charging cycles to ensure it doesn’t overheat.

Safe Handling and Storage

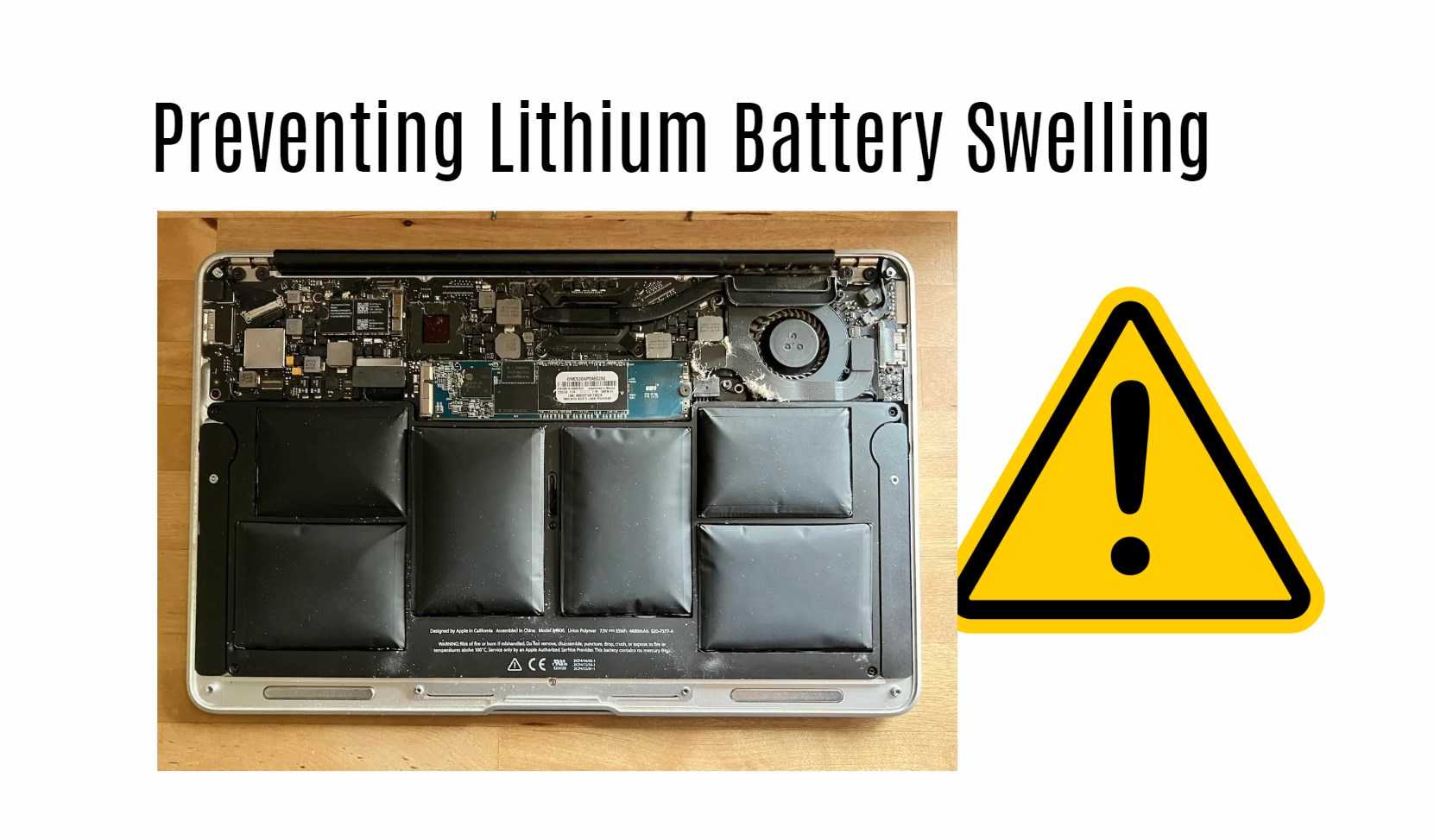

- Inspect Regularly: Frequently examine batteries for signs of damage such as bulging or punctures.

- Store Properly: Keep batteries in a cool, dry place, away from direct sunlight and high temperatures.

- Use Battery Cases: Store and transport batteries in protective cases to prevent physical damage and short circuits.

Operational Guidelines

- Avoid Extreme Conditions: Do not expose batteries to extreme temperatures or harsh environments.

- Prevent Water Exposure: Keep batteries away from water and other liquids to avoid short circuits.

- Proper Disposal: Dispose of old or damaged batteries at designated recycling centers to prevent environmental hazards.

Detailed Explanation of Contributing Factors

Overcharging

Overcharging is one of the primary causes of thermal runaway. Lithium-ion batteries, including 18650 cells, have a specified voltage range. Exceeding this range can cause internal overheating, leading to the breakdown of electrolyte and other components, which initiates a thermal runaway sequence.

Overdischarging

Overdischarging a battery can be equally detrimental. When the battery voltage drops below a critical level, the stability of the electrolyte and electrodes is compromised, increasing the risk of internal short circuits and subsequent thermal runaway.

Short-circuiting

A short circuit occurs when there is direct contact between the positive and negative terminals. This causes a rapid discharge of energy, generating significant heat that can trigger thermal runaway. This condition is often the result of mishandling or physical damage.

Physical Damage

Any physical compromise to the battery, such as punctures or severe impacts, can damage internal components. This damage can disrupt the protective layers within the battery, leading to a short circuit and eventual thermal runaway.

High Temperatures

Exposure to high ambient temperatures can accelerate the degradation of the battery’s internal materials. This degradation reduces the thermal stability of the battery, making it more susceptible to thermal runaway when exposed to additional stressors.

Poor Quality or Counterfeit Batteries

Substandard batteries often lack critical safety mechanisms such as thermal cut-off switches or pressure release vents. These batteries are more likely to fail under stress and enter a thermal runaway state.

Safety Guidelines to Prevent Explosions

- Purchase from Reputable Sources: Ensure batteries come from verified manufacturers.

- Avoid Overcharging: Use chargers with built-in overcharge protection.

- Inspect for Damage: Regularly check for signs of wear and tear.

- Store in Safe Conditions: Keep batteries in a controlled environment.

- Use Protective Cases: Store and transport batteries in cases to avoid physical damage.

- Avoid Water Exposure: Keep batteries dry to prevent short circuits.

- Dispose Responsibly: Recycle batteries at appropriate facilities.

Conclusion

By understanding the factors that lead to thermal runaway and implementing stringent safety protocols, the risks associated with 18650 batteries can be significantly minimized. Adhering to these guidelines will ensure safer usage and enhance the longevity of the batteries, making them reliable power sources for various applications.

FAQs

What makes 18650 batteries explode?

18650 batteries can explode primarily due to internal short circuits caused by a failure of the plastic separator, allowing the anode and cathode to touch. This generates excessive heat, leading to thermal runaway. Other factors include overcharging, poor-quality manufacturing, and exposure to extreme temperatures, all of which can compromise battery integrity.

What causes a lithium battery to explode?

Lithium batteries can explode due to several factors, including overcharging, manufacturing defects, and thermal runaway. Thermal runaway occurs when the battery overheats, causing a chain reaction that releases energy rapidly. Damage to the battery, such as punctures or exposure to high temperatures, can also lead to fires or explosions.

What is the problem with 18650 batteries?

The primary issues with 18650 batteries involve safety risks like overheating and potential explosions due to internal short circuits. Poor manufacturing quality can lead to defects that increase these risks. Additionally, improper charging practices and exposure to extreme conditions can exacerbate these problems, making careful handling essential.

What is the most common cause of battery explosions?

The most common cause of battery explosions is overcharging, which leads to excessive gas buildup and pressure within the battery. Other significant causes include internal short circuits from manufacturing defects or damage, thermal runaway due to overheating, and external ignition sources like sparks or flames.